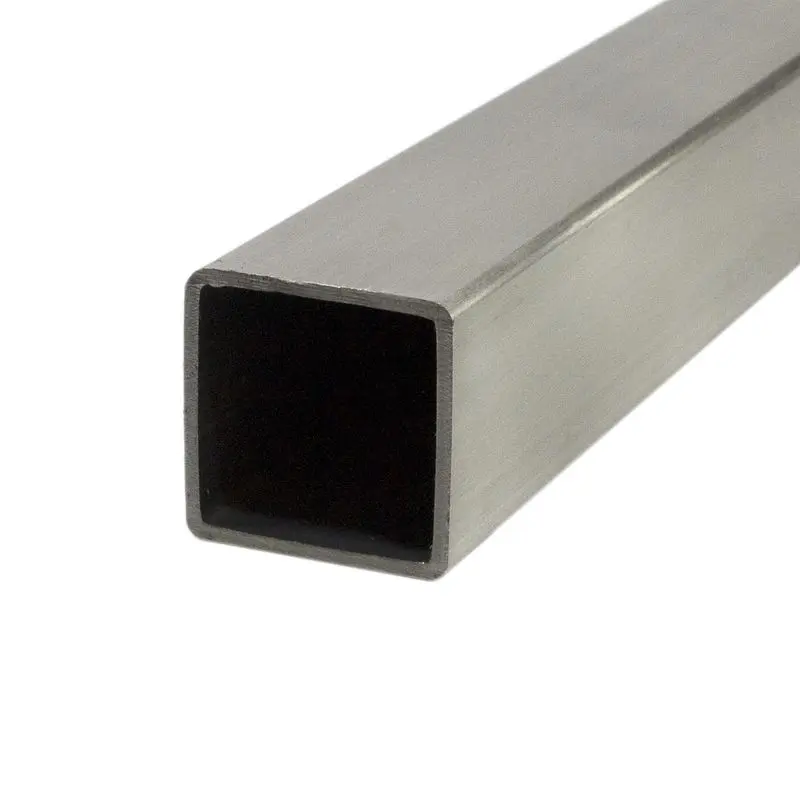

Wholesale stainless square tube, quality deal

specification

|

Product Name |

Stainless steel square tube |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

304、316、201、430、SS Duplex |

|

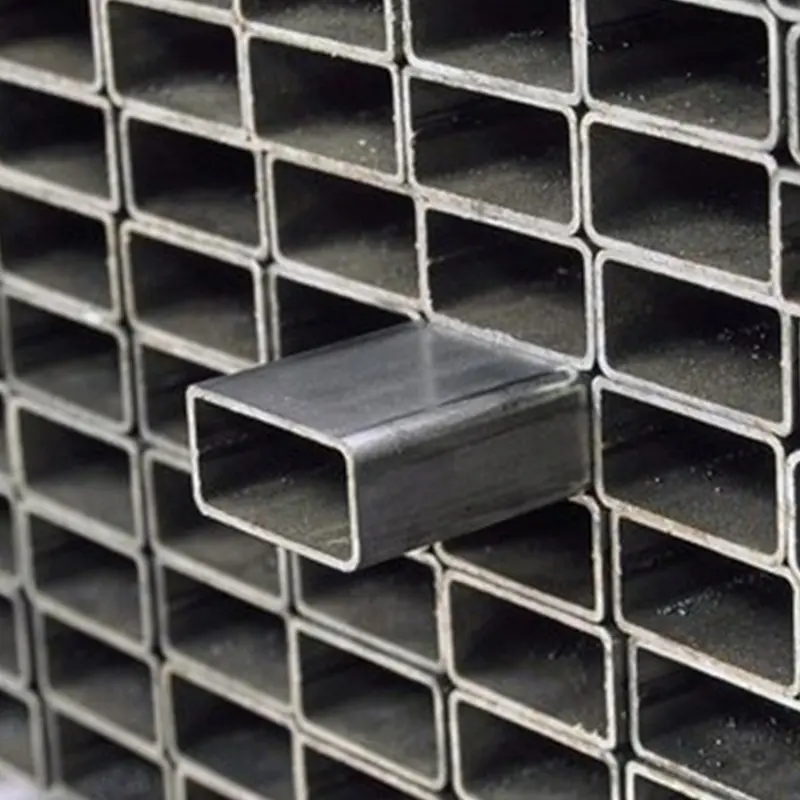

Outer diameter range |

Small square tube: The outer diameter is generally between 10mm and 50mm, suitable for some small structures and decorative purposes. Medium square tube: The outer diameter is generally between 50mm and 100mm, and is widely used in construction, machinery, furniture and other fields. Large square tube: The outer diameter is generally between 100mm and 300mm, suitable for load-bearing structures and large equipment. Extra Large Square Tube: The outer diameter exceeds 300mm, usually used for special projects and heavy structures. |

|

Thickness range |

Thin-wall square tube: The thickness is generally between 1mm and 3mm, suitable for light structures and decorative purposes. Medium thickness square tube: The thickness is generally between 3mm and 6mm, and is widely used in construction, machinery, furniture and other fields. Thick-walled square tube: The thickness is generally between 6mm and 12mm, suitable for load-bearing structures and heavy equipment. Extra thick square tube: The thickness exceeds 12mm, usually used in special projects and occasions with high strength requirements. |

|

Length range |

Customized length according to customer's special requirements. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

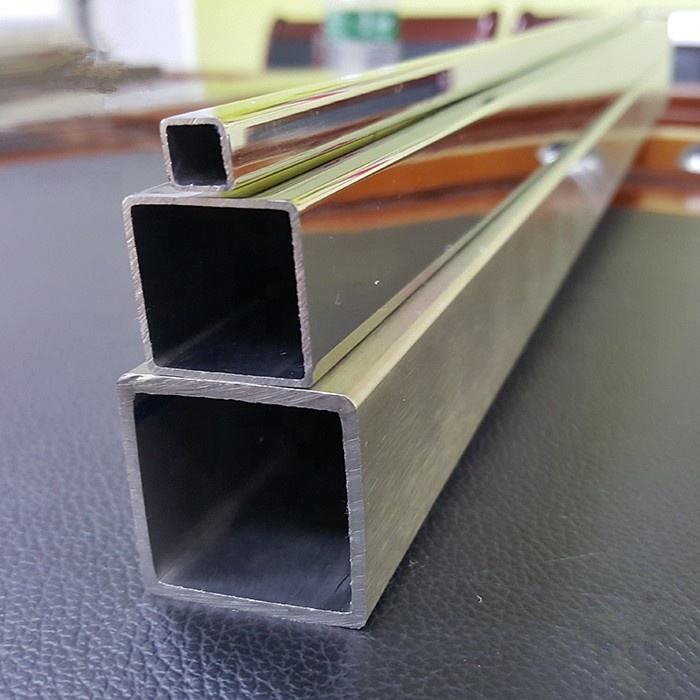

Surface treatment |

Pickling and passivation, galvanizing, painting, plastic spraying, shot blasting, rust removal, polishing |

|

Country of origin |

China |

|

Main Applications |

1.Construction Industry: Used in building structures, frames, railings, stairs, etc. to provide strength and stability. |

|

2.Mechanical Manufacturing: As brackets, frames and components of mechanical equipment, suitable for various industrial equipment. |

|

|

3.Furniture Manufacturing: Used to make stainless steel furniture, such as tables, chairs, shelves, etc., which are popular for their durability and easy cleaning. |

|

|

4.Automotive industry: Used in automotive structural parts and decorative parts to improve the durability and appearance of the car. |

|

|

5.Chemical Industry: Used in chemical equipment and pipelines, suitable for handling various chemicals due to its corrosion resistance. |

|

|

6.Food and pharmaceutical industry: Used in food processing equipment and medical devices, as its hygiene and corrosion resistance meet relevant standards. |

|

|

7.Decoration industry: Used in building facades, interior decoration, etc., and is favored for its beauty and modern feel. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

Product Display

Production process

Choose suitable stainless steel plates or strips as raw materials. Commonly used materials include 304, 316, etc.

Cutting:

Cut stainless steel sheets or strips into required width and length for subsequent forming.

Molding:

The cut stainless steel strip is rolled into a tube by cold or hot rolling. The strip is gradually formed into the shape of a square tube by a roller press.

Welding:

During the forming process, the edges of the square tube will be welded. Commonly used welding methods include TIG welding, MIG welding, etc. to ensure the strength and sealing of the weld.

Cooling:

After welding, the square tube will go through a cooling process to reduce the temperature and stabilize its shape.

Straightening:

Use the straightening machine to straighten the square tube to ensure its flat shape and accurate size.

Cutting:

Cut the formed square tube into required lengths to meet customers’ specific needs.

Surface treatment:

Carry out surface treatment on the square tube, such as pickling, polishing, sand blasting, etc., to improve its corrosion resistance and aesthetics.

Inspection:

Conduct quality inspection on finished products, including dimensions, weld quality, surface defects, etc., to ensure compliance with relevant standards.

Packing and Delivery:

Qualified square tubes will be packaged and ready to be shipped to customers.