Quality stainless alloy pipes, corrosion - proof

specification

|

Product Name |

Stainless steel alloy pipe |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

304、316、321、430、446、410、420、2205、2507、17-4PH |

|

Outer diameter range |

Small diameter pipe: The outer diameter is generally between 6mm and 50mm, and is commonly used in small equipment and piping systems.

Medium diameter pipe: The outer diameter is generally between 50mm and 150mm, suitable for general industrial and construction purposes.

Large diameter pipe: The outer diameter is generally above 150mm, and can even reach 1000mm or larger. It is commonly used in pipeline systems in the petroleum, chemical, construction and other industries. |

|

Thickness range |

Small diameter pipe: For small diameter stainless steel pipes with an outer diameter of 6mm to 50mm, the wall thickness is usually between 0.5mm and 3mm.

Medium diameter pipe: For medium diameter stainless steel pipes with an outer diameter of 50mm to 150mm, the wall thickness is generally between 2mm and 8mm.

Large diameter pipe: For large diameter stainless steel pipes with an outer diameter of more than 150mm, the wall thickness can be from 5mm to 20mm, or even thicker, depending on the use requirements and pressure level. |

|

Length range |

Customized length according to customer's special requirements. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Polishing、Pickling、Electrolytic polishing、Sandblasting、Coating、Passivation、Passivation、Heat treatment |

|

Country of origin |

China |

|

Main Applications |

1.Chemical industry: used to transport various chemical media, especially corrosive liquids and gases. |

|

2.Oil and Gas: Used for oil and gas transmission pipelines, oil well pipes and natural gas pipelines, able to withstand high pressure and harsh environment. |

|

|

3.Food and Beverage: Used for food processing, storage and transportation, complying with hygiene standards and preventing contamination. |

|

|

4.Pharmaceutical industry: used in pharmaceutical equipment and pipelines to ensure the purity and safety of products. |

|

|

5.Architecture and Structure: Used in building structures, decoration and furniture to provide strength and beauty. |

|

|

6.Automotive industry: Used in exhaust systems, cooling systems and other components, with high temperature and corrosion resistance. |

|

|

7.Aerospace: Used for structures and pipes of aircraft and spacecraft, requiring high strength and light weight. |

|

|

8.Heat exchanger: used for heat exchange equipment, able to withstand high temperature and high pressure. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

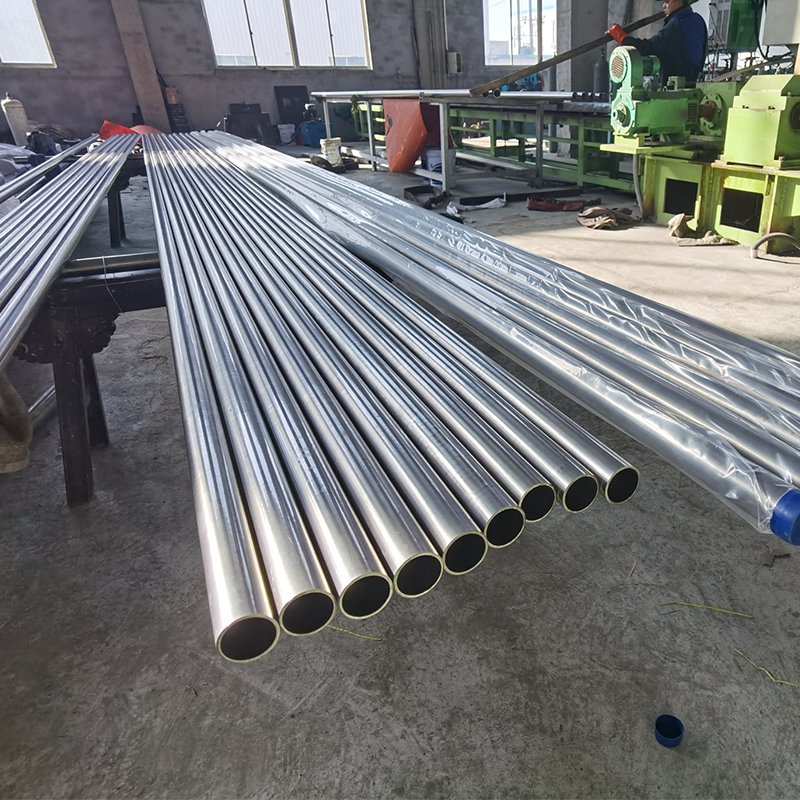

Product Display

Advantages

Excellent corrosion resistance: Stainless steel alloy pipes contain alloy elements such as chromium, which can maintain good corrosion resistance in a variety of corrosive environments and are suitable for industries such as chemical, food processing and marine.

High strength and toughness: Stainless steel alloy pipes have high strength and toughness, can withstand greater pressure and impact, and are suitable for high-load applications.

High temperature resistance: Stainless steel alloy tubes can still maintain good mechanical properties in high temperature environments and are suitable for high temperature equipment such as boilers and heat exchangers.

Good processing performance: Stainless steel alloy pipes are easy to process and form, and are suitable for processing operations such as welding, cutting and bending.

Aesthetics: Stainless steel alloy tubes have a smooth surface and good appearance, and are suitable for applications that require appearance, such as architectural decoration and household items.

Low Maintenance Cost: Due to their corrosion and wear resistance, stainless steel alloy pipes generally require less maintenance, reducing costs in long-term use.

Environmental protection: Stainless steel alloy pipes can be recycled, meet modern environmental protection requirements, and reduce the impact on the environment.

Production process

.Raw material preparation:

Select the appropriate stainless steel alloy material, usually stainless steel plate or stainless steel strip, according to the product specifications and requirements.

.Cutting:

Cut stainless steel sheets or strips into required sizes for subsequent forming and processing.

.Molding:

The cut material is formed into a tube by cold rolling or hot rolling. Cold rolling is suitable for small diameter tubes, and hot rolling is suitable for large diameter tubes.

.Welding:

For welded pipes, use appropriate welding process (such as TIG welding, MIG welding, etc.) to weld the edges of the pipes together to form a complete pipe.

.Annealing:

Through the process of heating and cooling, the stress generated during welding is eliminated, and the mechanical properties and corrosion resistance of the pipeline are improved.

.Pickling and passivation:

Use pickling solution to remove surface oxides and impurities, followed by passivation treatment to enhance the corrosion resistance of stainless steel.

.Surface treatment:

Polishing, sandblasting or other surface treatments are performed according to customer requirements to enhance the appearance and performance of the pipes.

.Detection:

Carry out various tests on the produced stainless steel alloy pipes, including size, wall thickness, welding quality, corrosion resistance, etc., to ensure that the products meet the standards and customer requirements.

.Packaging and Shipping:

Pack qualified products and prepare to ship to customers.