Q235B Submerged Arc Welded Pipe High Quality Pipe

specification

|

Product Name |

Submerged Arc Welded Pipe |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

Q235、Q345、X42、X52、X60、X7、S235、S275、S355、API 5L |

|

Outer diameter range |

Small diameter submerged arc welded pipe: The outer diameter is usually between 100mm and 500mm. Medium diameter submerged arc welded pipe: The outer diameter is usually between 500mm and 1000mm. Large diameter submerged arc welded pipe: The outer diameter is usually above 1000mm, and can even reach 2000mm or larger. |

|

Thickness range |

Small diameter submerged arc welded pipe: The wall thickness is usually between 3mm and 12mm. Medium diameter submerged arc welded pipe: wall thickness is usually between 6mm and 20mm. Large diameter submerged arc welded pipe: The wall thickness is usually between 10mm and 30mm, or even thicker. |

|

Length range |

The longest length is 12 meters, and can be customized by customers |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Pickling, sandblasting, painting, hot-dip galvanizing, electroplating, anti-corrosion coating |

|

Country of origin |

China |

|

Main Applications |

1.Oil and gas transportation: Submerged arc welded pipes are widely used in oil and gas transportation pipelines because of their good strength and corrosion resistance. |

|

2.Water Conservancy Project: In water conservancy projects, submerged arc welded pipes are used for water pipelines, irrigation systems, etc. and can withstand higher water pressure. |

|

|

3.Building structure: Submerged arc welded pipes can be used for load-bearing components in building structures, such as steel frames, support columns, etc. |

|

|

4.Power Industry: In the power industry, submerged arc welded pipes are used for supporting structures of transmission lines and connections of power equipment. |

|

|

5.Chemical industry: Pipeline systems used in chemical plants carry various chemical media and require good corrosion resistance and strength. |

|

|

6.Shipbuilding: In shipbuilding, submerged arc welded pipes are used for hull structures and other load-bearing components. |

|

|

7.Mechanical Manufacturing: Used to manufacture frames and supporting structures for various mechanical equipment. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

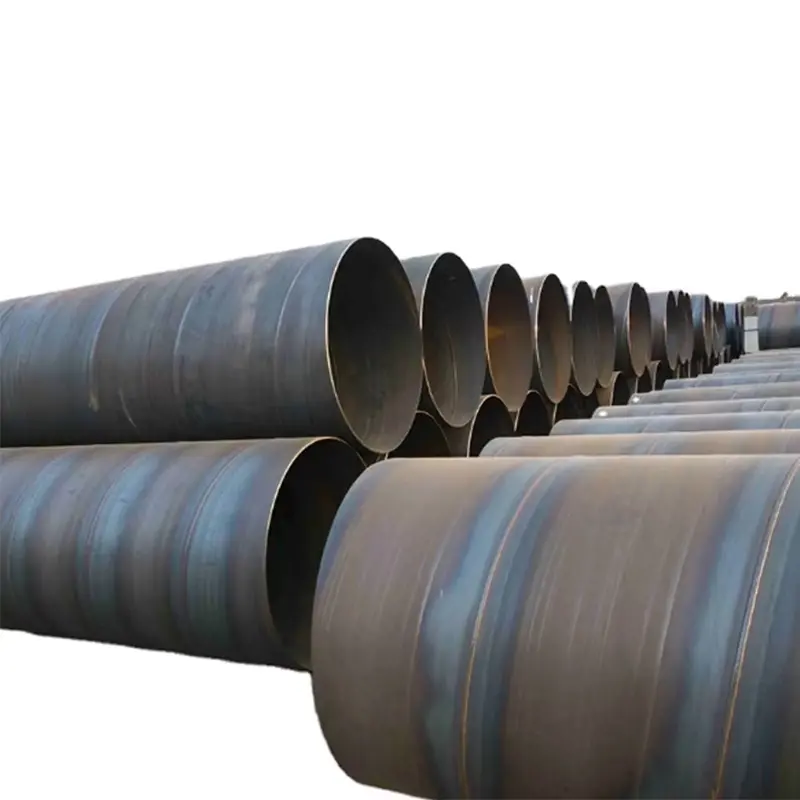

Product Display

Classification of Submerged Arc Welded Pipes

Classification by purpose:

Transmission pipeline: used for the transportation of fluids such as oil, natural gas, and water.

Structural pipe: used for structural parts such as buildings, bridges, and machinery.

Classification by outer diameter:

Small diameter submerged arc welded pipe: The outer diameter is usually between 100mm and 500mm.

Medium diameter submerged arc welded pipe: The outer diameter is usually between 500mm and 1000mm.

Large diameter submerged arc welded pipe: The outer diameter is usually above 1000mm.

Classification by wall thickness:

Thin-wall submerged arc welded pipe: thinner wall thickness, suitable for low-pressure fluid transportation.

Thick wall submerged arc welded pipe: thicker wall, suitable for high pressure fluid transportation or load-bearing structures.

Classification by material:

Carbon Steel Submerged Arc Welded Pipe: Commonly used for general purposes.

Alloy Steel Submerged Arc Welded Pipe: used for applications with special requirements, such as high temperature and high pressure environments.

Stainless steel submerged arc welded pipe: used in situations where high corrosion resistance is required.

Classification by welding method:

LSAW pipe: The weld is along the length of the pipe.

Spiral submerged arc welded pipe: The weld is spiral, suitable for large diameter pipes.

Advantages

High welding quality: The submerged arc welding process can achieve deep penetration and high welding speed, with stable weld quality and low defect rate, which is suitable for large-scale production.

High production efficiency: Submerged arc welding has a fast welding speed, which can improve production efficiency, shorten production cycle and reduce production costs.

Strong adaptability: Submerged arc welded pipes can produce pipes of various specifications and materials to meet different application requirements, including small and large diameter pipes.

Excellent mechanical properties: Submerged arc welded pipes have good mechanical properties, can withstand higher pressure and load, and are suitable for occasions with high strength requirements.

Strong corrosion resistance: Through proper surface treatment and material selection, submerged arc welded pipes can have good corrosion resistance and are suitable for use in harsh environments.

Small welding deformation: The heat input of submerged arc welding is relatively low, and the deformation produced during welding is small, which helps to maintain the geometric shape of the pipeline.

Suitable for large-scale production: The production process of submerged arc welded pipes is suitable for large-scale production and can meet the market demand for pipes.

Environmental protection: The smoke and gas emissions during submerged arc welding are relatively low and relatively environmentally friendly.

Production process

Raw material preparation:

Choose the appropriate steel plate or steel strip as raw material, usually according to the specifications and purpose of the pipeline.

Inspect raw materials to ensure their chemical composition and mechanical properties meet the standards.

Cutting:

Cutting steel sheets or strips into required width and length for subsequent forming and welding.

Molding:

The cut steel plate or steel strip is bent through a forming machine to form the preliminary shape of the pipe. The forming method can be straight seam forming or spiral forming.

Welding:

Welding is done using submerged arc welding. During the welding process, the welding wire and flux melt under the arc light to form a weld. The characteristics of submerged arc welding are fast welding speed and high weld quality.

After welding, inspect the weld to ensure that the welding quality meets the standards.

Heat treatment (optional):

Heat treatment is performed on the welded pipe to eliminate the internal stress generated during the welding process and improve the mechanical properties of the pipe.

Surface treatment:

Surface treatment of pipes, such as pickling, sandblasting, painting or hot-dip galvanizing, etc., to improve their corrosion resistance and aesthetics.

Inspection and testing:

Carry out various inspections and tests on finished pipes, including appearance inspection, dimension measurement, non-destructive testing of welds (such as ultrasonic testing, radiographic testing, etc.) and pressure testing, to ensure that product quality meets standards.

Packaging and delivery:

Pack qualified submerged arc welded pipes and prepare to ship to customers.