Q225\Q345 galvanized rectangular tube

specification

|

Product Name |

Galvanized rectangular tube |

|

Standard |

ASTM A53、ASTM A500、GOST 3262、BS 1387、DIN 2440、JIS G3444, etc. |

|

Material |

Q195, Q215, Q235, Q345, A36、A500、A500 Grade A、B、C、St3、St20、S235、S275、St37、St52、SS400、SS490, etc. |

|

Zinc Layer |

50 microns to 200 microns |

|

Outer diameter range |

American Standard (ASTM): ASTM A500: The outer diameter range is usually 1 inch (about 25.4 mm) to 12 inches (about 304.8 mm), and the specific size can be customized according to needs. British Standard (BS): BS 1387: The outer diameter range is usually 1/2 inch (about 12.7 mm) to 6 inches (about 168.3 mm), and the specific size can be customized according to requirements. German Standard (DIN): DIN 2440: The outer diameter range is generally 20 mm to 200 mm, and the specific size can be customized according to requirements. Japanese Standard (JIS): JIS G3466: The outer diameter range is usually 20 mm to 300 mm, and the specific size can be customized according to requirements. Russian Standard (GOST): GOST 3262: The outer diameter range is generally 15 mm to 200 mm, and the specific size can be customized according to requirements. |

|

Thickness range |

American Standard (ASTM): ASTM A500: Wall thickness typically ranges from 0.5 inches (about 1.27 mm) to 0.25 inches (about 6.35 mm), and specific thickness can be customized upon request. British Standard (BS): BS 1387: Wall thickness typically ranges from 1.5 mm to 5.0 mm, depending on the outside diameter of the pipe. German Standard (DIN): DIN 2440: Wall thickness generally ranges from 2.0 mm to 6.0 mm, depending on the outer diameter of the pipe. Japanese Standard (JIS): JIS G3466: Wall thickness ranges typically from 1.5 mm to 6.0 mm, depending on the outer diameter of the pipe. Russian Standard (GOST): GOST 3262: The wall thickness range is generally 1.5 mm to 10 mm, and the specific requirements may depend on the use environment. |

|

Length range |

The longest length is 6 meters, and can be customized by customers |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Country of origin |

China |

|

Main Applications |

1.Construction Industry: Used in building structures, support frames, fences, stair handrails, etc., providing good strength and corrosion resistance. |

|

2.Machinery manufacturing: Used to manufacture frames and supporting structures for various mechanical equipment due to its high strength and ease of processing. |

|

|

3.Furniture Manufacturing: Used in making furniture such as tables, chairs, shelves, etc. due to its beautiful appearance and durability. |

|

|

4.Transportation: Used in parts of vehicles such as automobiles and motorcycles to provide strength and corrosion resistance. |

|

|

5.Power Industry: Cable protection tubes used in power transmission and distribution systems to ensure the safety and durability of cables. |

|

|

6.Agriculture: Provides corrosion-resistant solutions for greenhouse structures, irrigation systems and agricultural equipment. |

|

|

7.Industrial Equipment: Used in various industrial equipment and machinery structural parts to ensure their service life in harsh environments. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

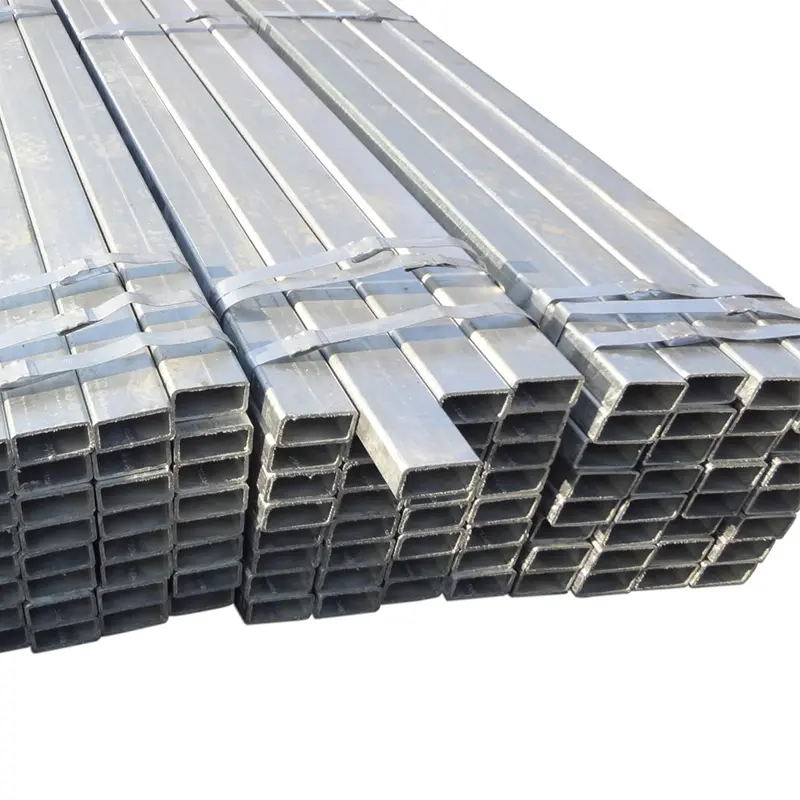

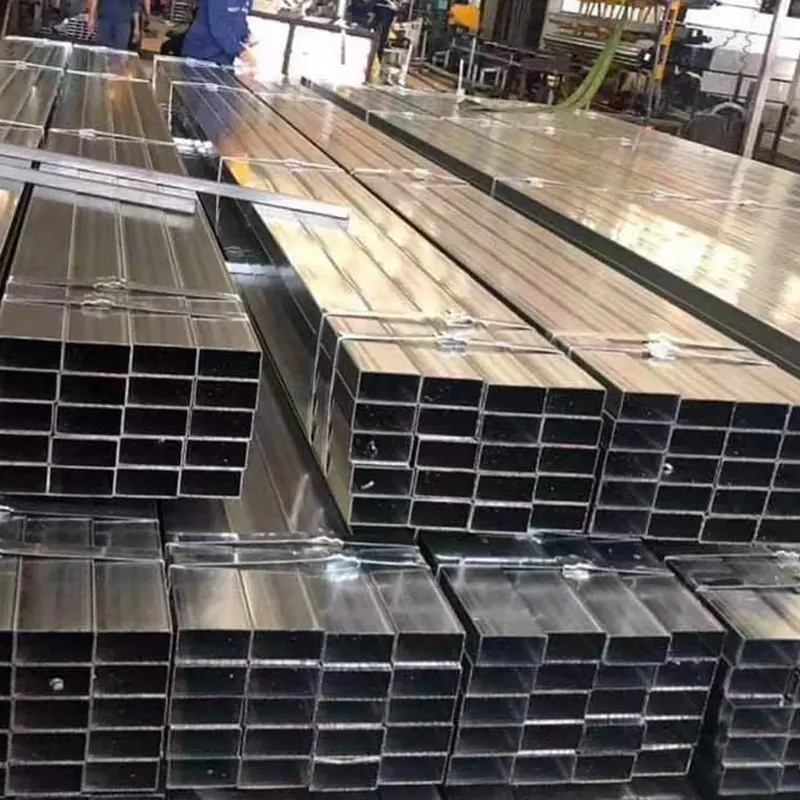

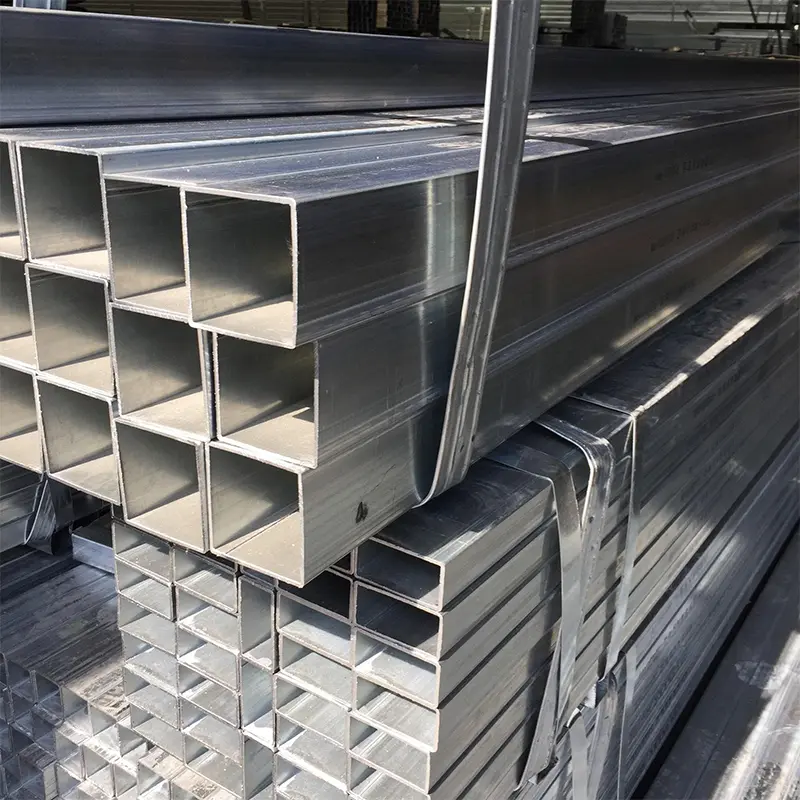

Product Display

The difference between galvanized rectangular tube and galvanized square tube

1.Shape

Galvanized Rectangular Tube: Has a rectangular cross-section with different lengths of long and short sides, usually used in structures that require a larger load-bearing capacity.

Galvanized square tube: It has a square cross-section with four sides of equal length, suitable for applications with high symmetry requirements.

2.Size

Galvanized rectangular tube: The external dimensions can be customized as needed, and the aspect ratio can be changed to suit different engineering requirements.

Galvanized square tube: The overall dimensions are usually uniform, and common specifications include 20mm x 20mm, 30mm x 30mm, etc., which are suitable for standardized applications.

3.Application

Galvanized rectangular tube: commonly used in building structures, support frames, fences, machinery manufacturing and other occasions that need to bear large loads.

Galvanized square tube: Widely used in furniture manufacturing, decoration, transportation and other fields because of its beautiful appearance and easy processing.

4.Strength and stiffness

Galvanized Rectangular Tube: Due to its shape, it usually performs better in terms of load-bearing capacity and stiffness and is suitable for use in load-bearing structures.

Galvanized Square Tube: While also offering good strength, in some cases rectangular tubing may provide better support in a particular direction.

5.Manufacturing process

The manufacturing process of the two is similar, usually produced by cold rolling or hot rolling process, and then galvanized, but in the forming process, the molds and processes of rectangular tubes and square tubes may be different.

Comparison of production processes of galvanized rectangular tubes and galvanized square tubes

1.Raw material preparation

Galvanized rectangular tube: Usually use steel strips or steel plates of different widths and thicknesses, which are cut and formed.

Galvanized Square Tube: Use steel strip or steel plate of equal width and thickness, cut into a square shape.

2.Molding process

Galvanized rectangular tube:

After the steel strip is rolled, it forms a rectangular tubular structure, which usually needs to be formed and adjusted several times to ensure that the dimensions of the long and short sides meet the requirements.

Galvanized Square Tube:

After the steel strip is rolled, it forms a square tubular structure. The forming process is relatively simple because the lengths of the four sides are equal.

3.Welding process

The welding process for both is usually similar, using methods such as high frequency welding or arc welding, but when welding, rectangular tubes may require more precise control to ensure the strength and appearance of the welded joint.

4.Cooling and solidification

After welding, both pipes need to cool and solidify, but due to the different shapes, the cooling method and time may be different.

5.Surface treatment

Both Galvanized rectangular tube and Galvanized square tube require cleaning, degreasing and rust removal on the surface, and then galvanizing. The galvanizing method (hot-dip galvanizing or electro-galvanizing) is usually the same, but during the processing, the processing time and method of rectangular tubes and square tubes may be different.

6.Inspection and Testing

During the inspection and testing phase, the standards and requirements for the two pipes may be similar, but due to the different shapes, the specific inspection methods and tools may be different.

Summarize

Although the production process of galvanized rectangular tube and galvanized square tube is similar in many aspects, the specific forming, welding and inspection processes may be different due to their different shapes and sizes. The selection of the appropriate production process should be determined according to the specific requirements and application scenarios of the product.