Q195, Q235, Q345 electrogalvanized pipe

specification

|

Product Name |

Electrogalvanized pipe |

|

Standard |

ASTM A53、ASTM A500、GOST 3262、BS 1387、DIN 2440、JIS G3444, etc. |

|

Material |

Q195, Q215, Q235, Q345, A36、A500、A500 Grade A、B、C、St3、St20、S235、S275、St37、St52、SS400、SS490, etc. |

|

Zinc Layer |

50 microns to 200 microns |

|

Outer diameter range |

American Standard (ASTM): ASTM A53: Outside diameters typically range from 1/2 inch (approximately 12.7 mm) to 36 inches (approximately 914.4 mm). Russian Standard (GOST): GOST 3262: The outer diameter range is generally 15 mm to 200 mm, and the specific size can be customized according to requirements. British Standard (BS): BS 1387: Outside diameters typically range from 1/2 inch (approx. 12.7 mm) to 6 inches (approx. 168.3 mm). German Standard (DIN): DIN 2440: The outer diameter range is generally from 21.3 mm to 168.3 mm. Japanese Standard (JIS): JIS G3444: The outer diameter range is usually 13.5 mm to 300 mm. |

|

Thickness range |

American Standard (ASTM): ASTM A53: Wall thickness typically ranges from 0.3 inches (about 7.62 mm) to 0.5 inches (about 12.7 mm), depending on the size and grade of pipe. Russian Standard (GOST): GOST 3262: The wall thickness range is generally 1.5 mm to 10 mm, and the specific requirements may depend on the use environment. British Standard (BS): BS 1387: Wall thickness typically ranges from 2.0 mm to 6.0 mm, depending on the outside diameter of the pipe. German Standard (DIN): DIN 2440: Wall thickness generally ranges from 2.0 mm to 6.0 mm, depending on the outer diameter of the pipe. Japanese Standard (JIS): JIS G3444: Wall thickness typically ranges from 1.5 mm to 6.0 mm, depending on the outer diameter of the pipe. |

|

Length range |

The longest length is 6 meters, and can be customized by customers |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Country of origin |

China |

|

Main Applications |

1.Construction Industry: Used in building structures, support frames, fences, stair handrails, etc., providing good strength and corrosion resistance. |

|

2.Plumbing and drainage systems: For use in water supply pipes and drainage systems, especially where corrosion protection is required. |

|

|

3.Power Industry: Cable protection tubes used in power transmission and distribution systems to ensure the safety and durability of cables. |

|

|

4.Agriculture: Provides corrosion-resistant solutions for greenhouse structures, irrigation systems and agricultural equipment. |

|

|

5.Furniture and Household Goods: Used in the manufacture of furniture, shelving, and other household items for its aesthetic appearance and durability. |

|

|

6.Transportation: Used in automobile, motorcycle and other transportation components to provide strength and corrosion resistance. |

|

|

7.Industrial Equipment: Used in various industrial equipment and machinery structural parts to ensure their service life in harsh environments. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

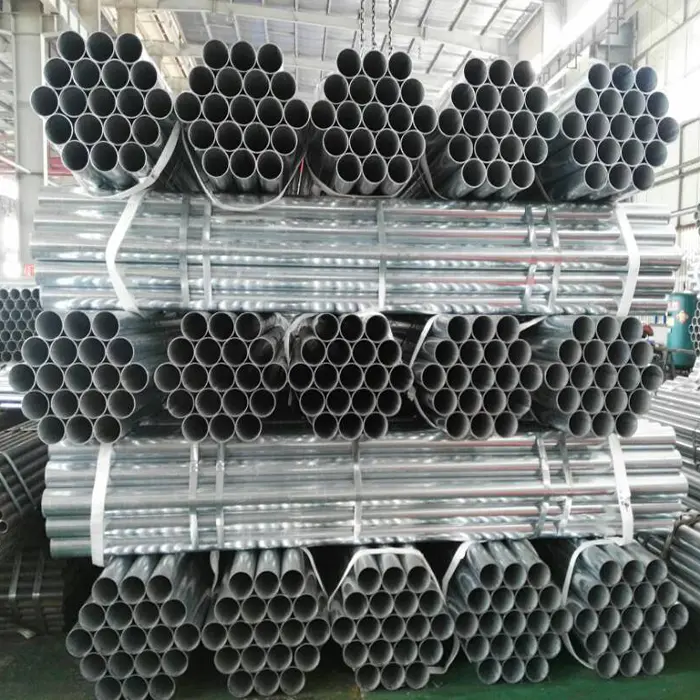

Product Display

Classification of electrogalvanized pipes

.Classification by standard:

American Standard (ASTM): such as ASTM A53, ASTM A500, etc.

British Standard (BS): such as BS 1387, etc.

German Standard (DIN): such as DIN 2440, etc.

Japanese Standard (JIS): such as JIS G3444, etc.

Russian Standard (GOST): such as GOST 3262, etc.

.Classification by purpose:

Structural pipes: used in structural applications such as buildings, bridges, etc.

Fluid delivery pipe: used for the delivery of fluids such as water and gas.

Cable protection tube: used to protect cables in the power industry.

.Classification by manufacturing process:

Welded Pipe: Pipe manufactured by welding process, suitable for most applications.

Seamless Pipe: Pipe manufactured by extrusion or rolling process, usually used for high pressure and high strength applications.

.Classification by outer diameter and wall thickness:

According to the difference in outer diameter and wall thickness, electro-galvanized pipes can be divided into different specifications and grades to meet different engineering needs.

.Classification by zinc layer thickness:

According to the thickness of the zinc layer, it can be divided into light galvanized pipe and heavy galvanized pipe, suitable for different corrosion environments.

Advantages

.Excellent corrosion resistance:

Electrogalvanized pipes are coated with a layer of zinc, which effectively prevents oxidation and corrosion, extending the service life of the pipes, especially in humid or corrosive environments.

.Strength and toughness:

Electro-galvanized pipes are usually made of carbon steel, which has good mechanical strength and toughness and can withstand greater pressure and impact.

.Economical:

Compared with other materials such as stainless steel, electro-galvanized pipes have lower costs, are suitable for large-scale applications, and have good cost-effectiveness.

.Easy to process and install:

Electro-galvanized pipes can be easily cut, welded and connected, suitable for various construction and installation needs.

.Aesthetics:

Electro-galvanized pipes have a smooth surface and a clean appearance, making them suitable for visible architectural and decorative applications.

.Environmental protection:

Zinc is a recyclable material. Electrogalvanized pipes can be recycled after their service life, which meets the requirements of sustainable development.

.Diverse Applications:

Electro-galvanized pipes can be widely used in construction, agriculture, transportation, industry and other fields with strong adaptability.

Production process

.Raw material preparation:

Select appropriate carbon steel coils or steel pipes as raw materials, ensuring they meet relevant standards and specifications.

.Tube forming:

The steel coil is processed into the required pipe shape through cold or hot rolling process. For welded pipes, steel strip or steel plate is usually formed into a pipe shape by rolling and welding.

.Welding:

For welded pipes, the edges of the pipes are welded together using processes such as high frequency welding or arc welding to form a complete pipe.

.Pipe cutting:

Cut the welded pipes to the required lengths, usually custom made to customer specifications.

.Surface treatment:

Clean the pipes to remove oil, rust and impurities on the surface to ensure the adhesion of the galvanized layer.

.Electrogalvanizing:

Immerse the cleaned pipe in a molten zinc bath for electro-galvanizing. The thickness and quality of the zinc layer can be controlled according to standard requirements.

.Cooling and curing:

After the pipe is removed from the zinc bath, it is cooled to allow the zinc layer to solidify and form a strong protective layer.

.Inspection and testing:

Conduct quality inspection on electro-galvanized pipes, including zinc layer thickness, appearance, dimensions and mechanical properties, to ensure they meet relevant standards.

.Packaging and Shipping:

Pack the qualified electro-galvanized pipes and prepare to ship them to customers.