Premium 304L SS Coil for Multiple Uses

specification

|

Stainless Steel Coil |

|

|

Product Name |

Stainless Steel Coil, Stainless Coil, SS Coil |

|

Standard |

GB, AISI, ASTM, DIN, EN, JIS |

|

Available Grades |

200 Series: 201,202 |

|

300 Series: 304, 304L, 304H, 309, 309S, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H |

|

|

400 Series: 409, 410S, 416, 420, 430, 439, 440, 444, 446 |

|

|

Duplex and Others: 2205, 2507, S31803, S32205, S32750, S32760, 253MA, 254SMO, 904L etc |

|

|

Process |

Hot Rolled, Cold Rolled |

|

Sizes |

Thickness: 0.1-16mm, Width: 600-2000mm (according to customer's request) |

|

Surface Treatment |

NO.1, 2B, NO.4, BA, HL, Mirror |

|

Inspection |

SGS, TUV, BV, ABS, LR etc. |

|

Application |

Oil&Gas, Petroleum, Vessels, Ship Building, Water Treatment And Environmental Protection etc. |

|

Finish |

Description |

Thickness (mm) |

Width (mm) |

|

2B |

Smooth finish, reflective grey sheen.Most widely used surface finish. |

0.55 |

914 & 1219 |

|

Bright Annealed (BA) |

Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. |

0.70 |

914 & 1219 |

|

Dull Polish (DP) |

Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. |

0.90 |

750, 914 & 1219 |

|

Hot Rolled (HR) |

Scaled finish, ideal if surface finish is not a key concern. |

1.20 |

750, 914, 1050, 1219 & 1500 |

|

No.1 |

Finished by hot-rolling,annealing and pickling, characterized by white pickled surface |

1.50 |

914, 1219 & 1500 |

|

HL |

finished by continuous liner polishing |

1.60 |

914, 1219 & 1500 |

|

No.4 |

polishing with No.150 to No.180 mesh |

2.00 |

914, 1219 & 1500 |

|

No.8 |

a mirror-like reflective surface by polishing |

2.50 |

914, 1219 & 1500 |

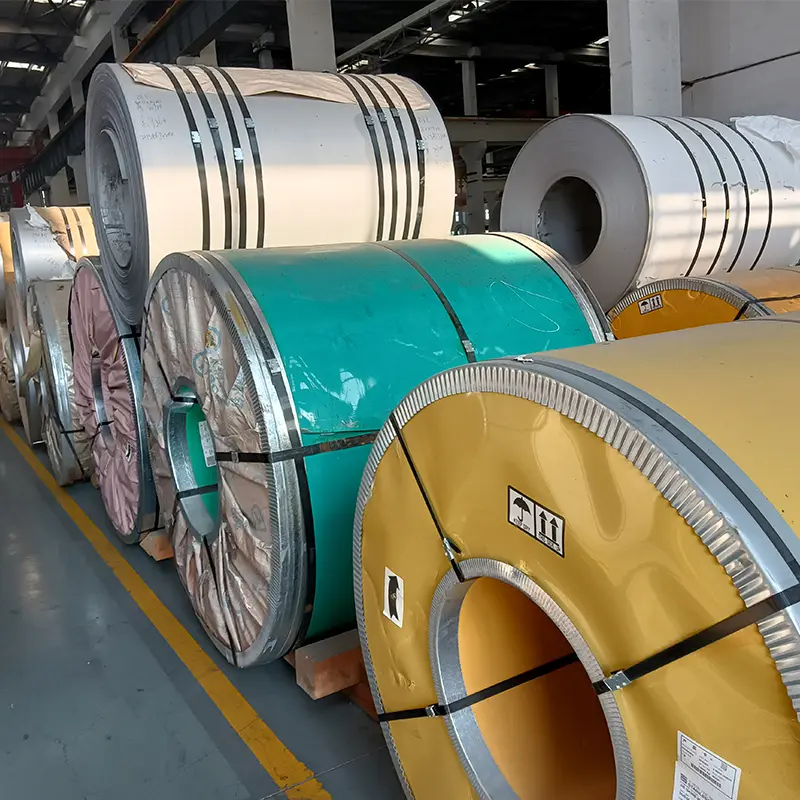

Product Display

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.03 |

≤1.0 |

≤ 2.0 |

18.0~20.0 |

8.0~12.0 |

≤ 0.03 |

≤ 0.035 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥ 520 |

≥ 205 |

≥ 40 |

≤ 187HB ;≤ 90HRB;≤ 200HV |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

8.03 |

193 |

16.9 |

16.2 |

72 |

Surface Selection