Innovative uses of carbon sq. Tubes

specification

|

Product Name |

Carbon steel square tube |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

Q235、Q345、S235、S355、A36 |

|

Outer diameter range |

Small diameter square tube: The outer diameter is generally between 20mm and 100mm, suitable for light structures and small equipment. Medium diameter square tube: The outer diameter is generally between 100mm and 300mm, suitable for general construction and structural purposes. Large diameter square tube: The outer diameter is generally between 300mm and 600mm, suitable for structures with high load-bearing requirements and large equipment. |

|

Thickness range |

Small diameter square tube: The wall thickness is generally between 1.5mm and 5mm. Medium diameter square tube: The wall thickness is generally between 3mm and 8mm. Large diameter square tube: The wall thickness is generally between 5mm and 12mm, or even thicker. |

|

Length range |

Customized length according to customer's special requirements. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Hot-dip galvanizing、Cold galvanizing、Plastic spraying、Phosphating、Pickling、Polishing |

|

Country of origin |

China |

|

Main Applications |

1.Construction Engineering: Carbon steel square tubes are often used in building structures, such as frames, supports, fences, etc., because of their high strength and strong bearing capacity. |

|

2.Mechanical Manufacturing: In mechanical equipment, carbon steel square tubes can be used as structural parts, brackets and frames to provide stable support. |

|

|

3.Furniture Manufacturing: Carbon steel square tubes are widely used to make various furniture, such as tables, chairs, shelves, etc., because of their beautiful appearance and easy processing. |

|

|

4.Transportation: In the manufacture of automobiles, ships and other means of transportation, carbon steel square tubes can be used for frames, brackets and other structural components. |

|

|

5.Power and Communication: Carbon steel square tubes can be used in the construction of infrastructure such as power towers and communication towers due to their durability and strength. |

|

|

6.Agriculture and Gardening: Carbon steel square tubes are also widely used in greenhouses, sheds and other agricultural facilities. |

|

|

7.Sports facilities: Carbon steel square tubes are often used to make sports equipment and facilities, such as basketball stands, fitness equipment, etc. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

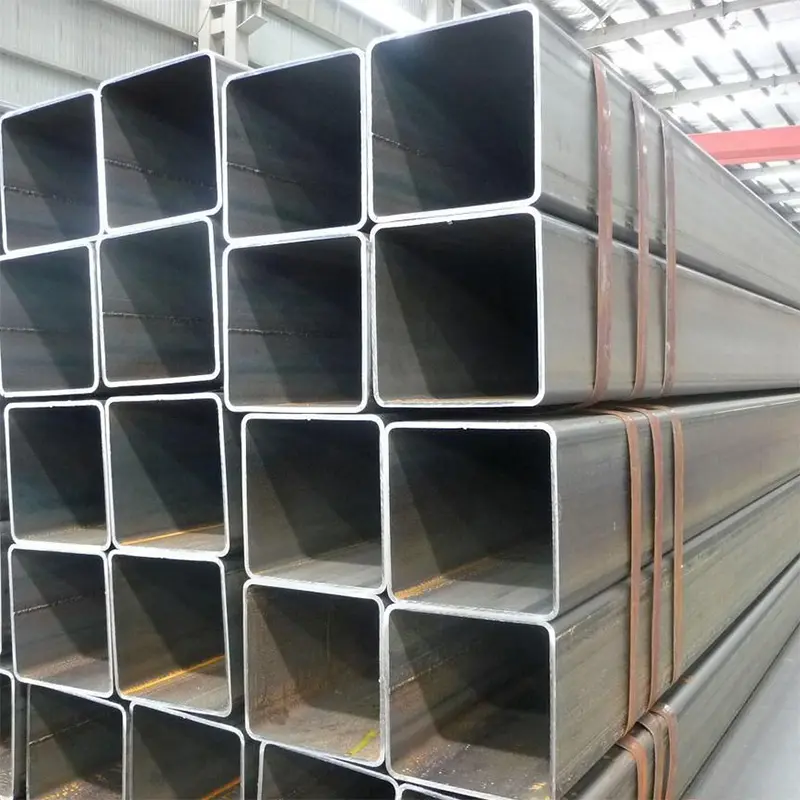

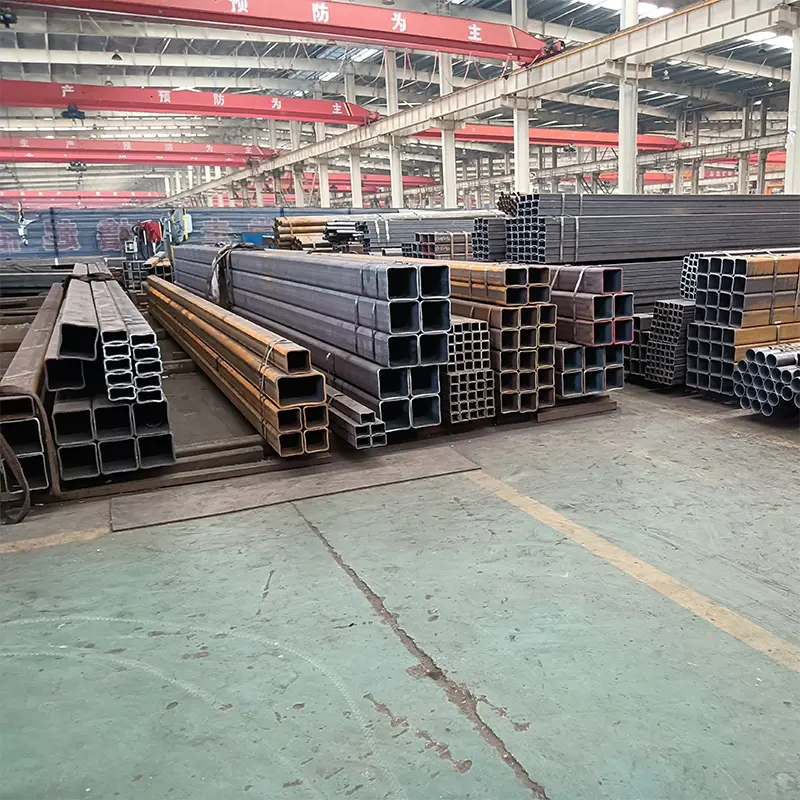

Product Display

Production process

.Raw material preparation:

Select suitable carbon steel coils or strips as raw materials and usually cut them according to the specifications and requirements of the products.

.Molding:

The steel strip is passed through a forming machine for cold or hot bending to form the preliminary shape of a square tube. During the forming process, the edges of the steel strip are folded into a tube shape.

.Welding:

Use high frequency welding or arc welding to weld the edges of the square tube together to form a complete square tube. The temperature and pressure need to be controlled during the welding process to ensure the quality of the welding.

.Cooling:

After welding is completed, the square tube will go through a cooling process to reduce the temperature and stabilize its shape.

.Cutting:

According to customer’s needs, the square tube is cut into the required length. Cutting can be done using a cutting machine or a sawing machine.

.Surface treatment:

Carry out surface treatment on the square tube, such as pickling, spraying, hot-dip galvanizing, etc., to improve its corrosion resistance and aesthetics.

.Inspection:

Carry out quality inspection on the produced square tubes, including appearance inspection, dimension measurement and welding quality inspection, etc., to ensure that the products meet the relevant standards and customer requirements.

.Packaging and delivery:

Pack qualified square tubes and prepare to ship to customers.