01

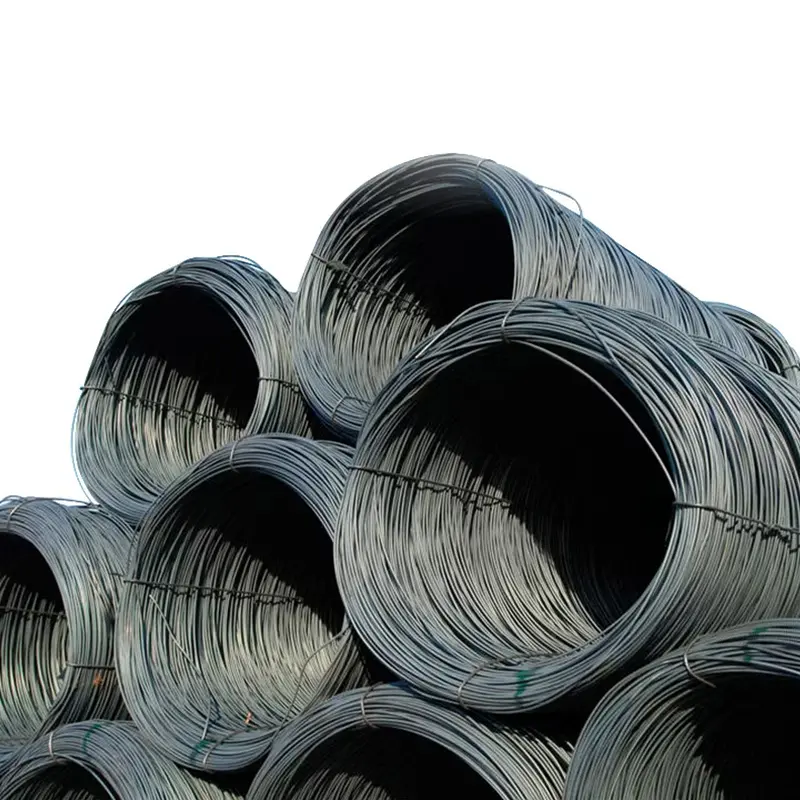

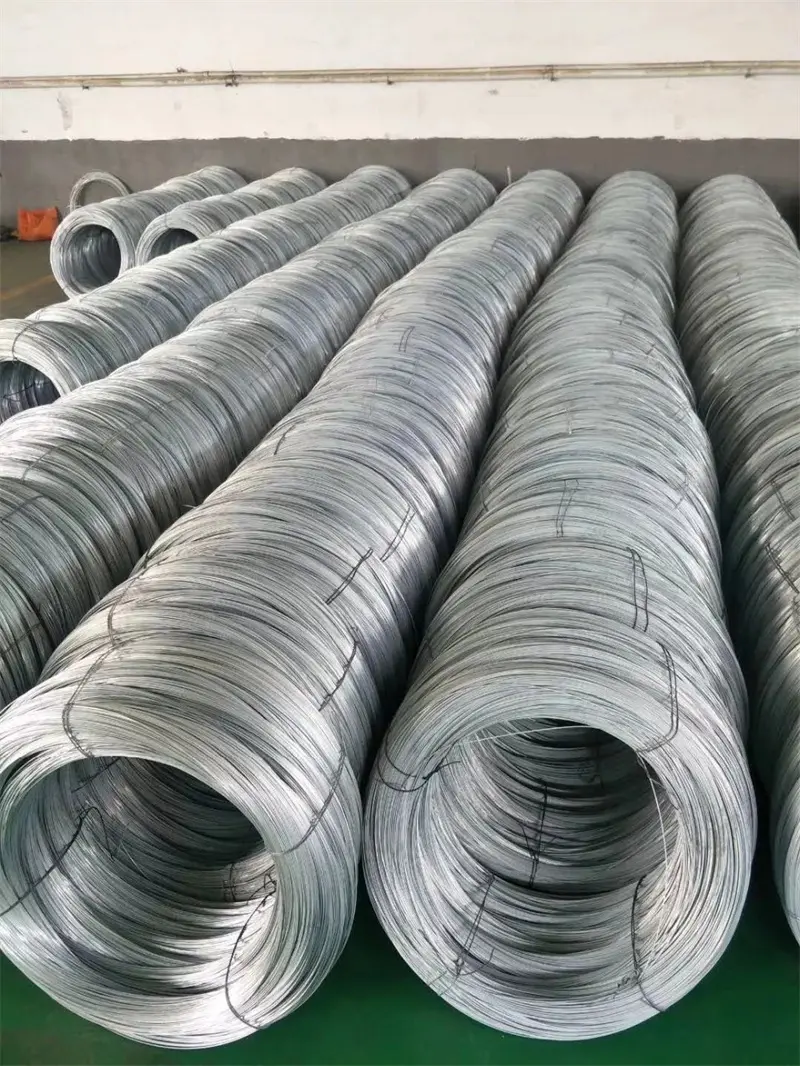

High - quality SAE - 1006 low - carbon wire

specification

| Product Name | SAE-1006 Steel Wire |

| Standard | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Diameter | Fine wire: The diameter is usually between 0.1 mm and 1.0 mm, and is commonly used in electronics, textiles and other industries. Medium wire: The diameter is usually between 1.0 mm and 5.0 mm, and is widely used in construction, machinery manufacturing and other fields. Thick wire: The diameter is usually between 5.0 mm and 20.0 mm, and is often used in heavy applications such as rebar and ropes. |

| Production Process | Hot Rolling, Cold Rolling |

| Error | ±1% |

| Certification | ISO 9001 ,CE,API |

| Surface treatment | Black/Peeling/Polished/Machined |

| Country of origin | China |

| Main Applications | Construction industry, manufacturing industry, electrical industry, automobile industry, household goods, agriculture, textile industry, packaging industry |

| Package | Roll packaging, bundling, reel packaging, bag packaging, pallet packaging, rust-proof packaging |

| Payment Term | TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

| After-sales service | 1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

Product Display

SAE-1006 Wire Rod Specifications

|

SAE-1006 Wire Rod Specifications |

||||

|

Nominal Diameter (mm) |

Permissible Deviation (mm) |

Nominal Cross Section (mm2) |

||

|

Nominal Weight (kg/m) |

Permissible out – of Roundness(mm) |

|||

|

5.5 |

-/+ 0.3 |

0.238 |

0.186 |

0.48 |

|

6.0 |

-/+ 0.3 |

0.283 |

0.222 |

|

|

6.5 |

-/+ 0.3 |

0.332 |

0.260 |

|

|

7.0 |

-/+ 0.4 |

0.385 |

0.302 |

0.64 |

|

(*)8.0 |

-/+ 0.4 |

0.503 |

0.395 |

|

|

(**)10.0 |

-/+ 0.4 |

0.785 |

0.617 |

|

|

(**)12.0 |

-/+ 0.4 |

1.131 |

0.888 |

|

|

(**)14.0 |

-/+ 0.4 |

1.539 |

1.208 |

|

|

(**)16.0 |

-/+ 0.5 |

2.011 |

1.578 |

0.80 |

SAE-1006 Wire Rod Chemical Composition

|

SAE-1006 Wire Rod Chemical Composition |

||||||||

|

Grade |

C% (max) |

Mn% |

Si% (max) |

S% (max) |

P% (max) |

Cr% (max) |

Ni% (max) |

Cu% (max) |

|

SAE 1006 |

0.08 |

0.30-0.40 |

0.08 |

0.025 |

0.020 |

0.10 |

0.10 |

0.15 |

Advantages

Good plasticity and weldability: The low carbon content of SAE-1006 steel wire makes it have good plasticity during processing, easy to form and weld, and suitable for various manufacturing processes.

Excellent strength and toughness: Although it is low carbon steel, after proper heat treatment and cold working, SAE-1006 steel wire can obtain higher strength and toughness, which is suitable for applications with certain loads.

Cost-effectiveness: Compared with high carbon steel or alloy steel, SAE-1006 steel wire has a lower production cost, is suitable for large-scale production, and can effectively reduce manufacturing costs.

Good surface quality: SAE-1006 steel wire generally has a good surface finish and is suitable for applications that require high surface quality, such as springs, cables, etc.

Corrosion resistance: Although the corrosion resistance of low carbon steel is relatively poor, its corrosion resistance can be significantly improved and its service life can be extended through surface treatment (such as galvanizing).

Wide Application: SAE-1006 steel wire is widely used in automobile, construction, machinery manufacturing and other fields, suitable for manufacturing various parts and structural parts.

Overall, SAE-1006 steel wire is an ideal choice for many industrial applications due to its excellent mechanical properties, economy and processability.