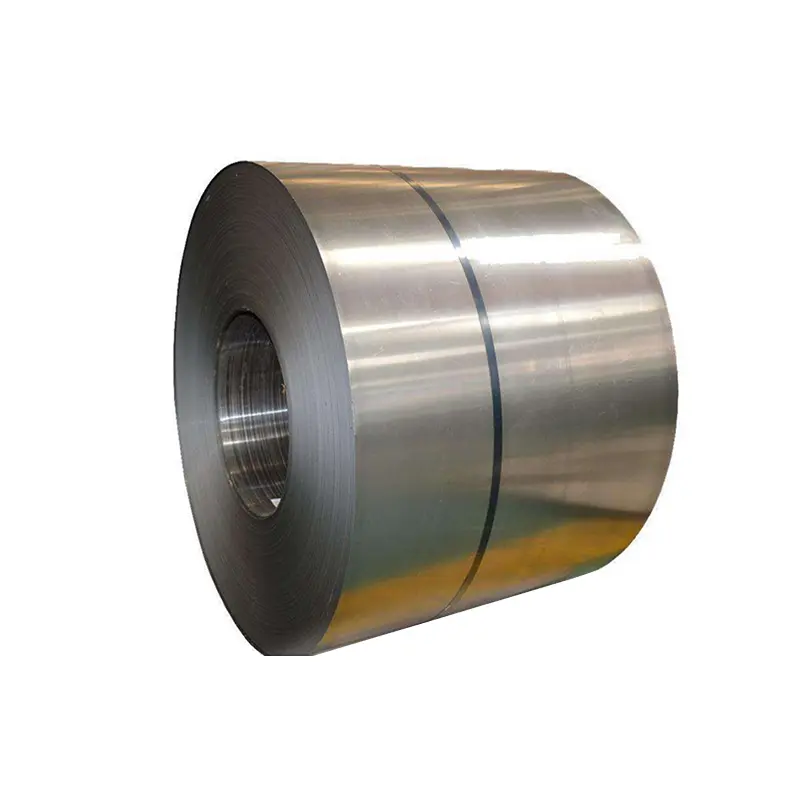

High - grade DX51D/SGCC Galvanized Coil

specification

| Product Name | DX51D/SGCC Galvanized Coil |

| Specification | Thickness: 0.11-4.75mm;customization |

| Width: 6-1500mm;customization | |

| Standard | ISO/ RoHS/ IBR/ AISI/ ASTM /GB/ EN / DIN /JIS |

| Material | Q195 Q235 Q345 SGCC SGCH SGC340 SGC400 SGC440 SGC490 SGC570 SGHC SGH340 SGH400 SGH440 SGH490 SGH540 DX51D DX52D DX53D DX54D DX55D DX56D DX57D S220GD S250GD S280GD S320GD S350GD S400GD S500GD S550GD SS230 SS250 SS275 |

| surface structure | zero spangle, regular spangle or normal spangle |

| Zinc Coating | 40g-250g 40g, 60g, 80g, 100g, 120g, 140g, 180g, 200g, 250g |

| Surface | Galvanized/black/oil/painting/customized |

| Package | Packed with woven bag and steel sheet, fixed on non-fumigation pallet. Could also packed as clients' request. |

| Price term | CIF FOB |

| Payment terms | T/T, L/C |

| Deliver time | Within 7-15 days after deposit,base on quantity. |

| Shipment | 20' container or bulk vessel |

| Others | We can do special orders as customer's requests. |

| We also can provide all kinds of steel coil. | |

| All the production process are made under the ISO9001:2008 strictly |

Product Display

Chemical Composition

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

Ti |

|

Forcold Forming Chinese Standard |

DX51D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

DX52D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX53D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX54D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX56D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX57D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

Forcold Forming Japanese Standard |

SGCC |

0.15 |

0.50 |

0.80 |

0.050 |

0.030 |

0.025 |

|

SGCD1 |

0.12 |

0.50 |

0.60 |

0.040 |

0.030 |

0.025 |

|

|

SGCD3 |

0.08 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

SGCD4 |

0.06 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

For Structure Japanese Standard |

SGC340 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.025 |

|

SGC400 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.150 |

|

|

SGC490 |

0.30 |

0.50 |

2.00 |

0.200 |

0.035 |

0.025 |

|

|

SGC510 |

0.30 |

0.50 |

2.50 |

0.200 |

0.035 |

0.025 |

|

|

For Structure AISI Standard |

S220GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

S250GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S280GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S320GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S350GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

|

|

S550GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

Mechanical Properties

|

Grade |

Yield Strength MPa≥ |

Tensile Strength MPa≥ |

Elongation A%≥ |

|

DX51D Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD Z/ZM/AM |

220 |

300 |

20 |

|

S250GD Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD Z/ZM/AM |

280 |

360 |

18 |

|

S300GD A/AM |

300 |

380 |

18 |

|

S320GD Z/ZM/AM |

320 |

390 |

17 |

|

S350GD Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD A/AM |

450 |

480 |

15 |

|

S550GD Z/ZM/AZ/AM |

550 |

550 |

- |

Galvanized Surface Selection

|

Zero Spangle |

Minimized Spangle |

Normal Spangle |

Large Spangle |

|

|

|

|

|

|

Use of The Environment |

Recommended Zinc Thickness |

|

Indoor Use |

Z10 or Z12 (100g/㎡or 120g/㎡) |

|

Suburbs |

Z20 and Painting (200g/㎡) |

|

Urban or Industrial Area |

Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Coastal Area |

Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Punch or Deep Drawing Application |

Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

|

Surface Treatment Type |

Code |

Features |

|

Chromic Acid Treatment |

C |

Good corrosion resistance, suitable for bare state |

|

Chromic Acid Treatment+Oiling |

S |

Good corrosion resistance |

|

Phosphoric Acid Treatment (Including Sealing Treatment) |

P |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling |

Q |

Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment) |

T |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling |

V |

Has a certain corrosion resistance, good paint performance, and prevent rust |

|

Oiling |

O |

Prevent rust during transportation and storage |

|

No Treatment |

M |

Suitable for immediate painting |

Material Comparison

|

Chinese Standard |

Japan Standard |

European Standard |

|

DX51D Z/DC51D Z (CR) |

SGCC |

DX51D Z |

|

DX52D Z/DC52D Z |

SGCD1 |

DX52D With |

|

DX53D Z/DC53D Z/DX54D Z/DC54D Z |

SGCD2/SGCD3 |

DX53D Z/DX54D Z |

|

S220/250/280/320/350/550GD Z |

SGC340/400/440/490/570 |

S220/250/280/320/350GD Z |

|

DX51D Z/DD51D Z (HR) |

SGHC |

DX51D Z |