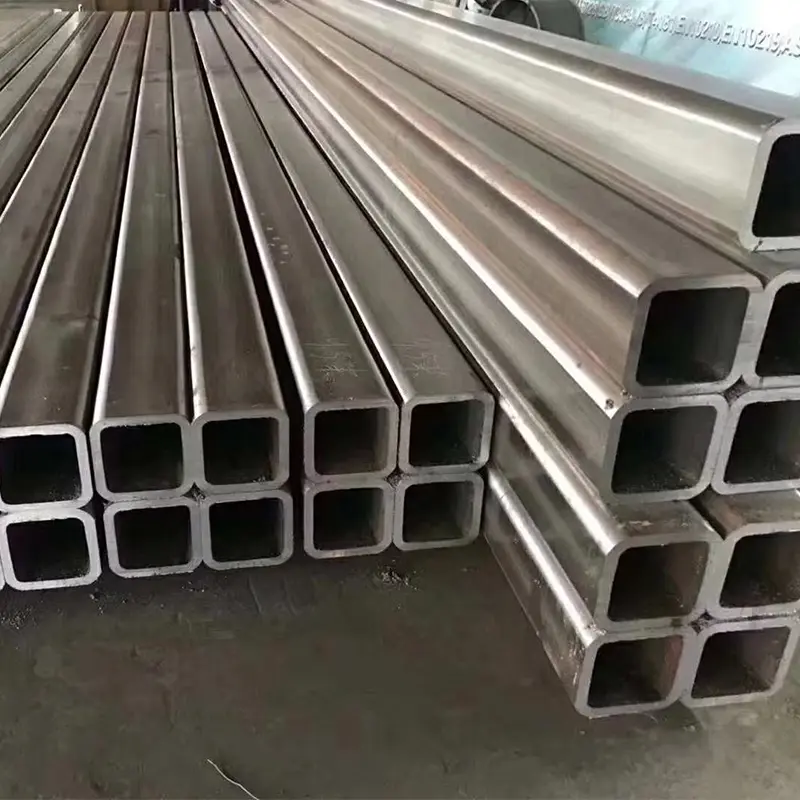

Explore seamless sq. tube versatility

specification

|

Product Name |

Seamless square tube |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

Q235、Q345、20#、45#、16Mn、20Cr、40Cr、30CrMo、42CrMo、15CrMo、304、316、321、310、430、Q390、Q420、Q460 |

|

Outer diameter range |

Small diameter seamless square tube: the outer diameter is generally between 20mm and 100mm. Medium diameter seamless square tube: the outer diameter is generally between 100mm and 300mm. Large diameter seamless square tube: the outer diameter is generally between 300mm and 600mm. |

|

Thickness range |

Small wall thickness seamless square tube: generally between 2mm and 5mm, suitable for light structures and low pressure applications. Medium wall thickness seamless square tube: generally between 5mm and 10mm, suitable for general structures and medium pressure applications. Large wall thickness seamless square tube: generally between 10mm and 30mm, suitable for high strength and high pressure applications. |

|

Length range |

Customized length according to customer's special requirements. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Pickling, sandblasting, galvanizing, spraying, electroplating, heat treatment, polishing |

|

Country of origin |

China |

|

Main Applications |

1.Construction Engineering: Used in building structures, supporting frames, stairs, guardrails, etc. to provide strength and stability. |

|

2.Mechanical manufacturing: used to manufacture mechanical parts, transmission shafts, brackets, etc., suitable for occasions with high loads. |

|

|

3.Oil and gas industry: Pipelines used to transport oil, natural gas and other fluids, with good pressure resistance. |

|

|

4.Chemical industry: used in chemical equipment, reactors, pipelines, etc., able to withstand corrosive media. |

|

|

5.Automobile industry: Used in automobile chassis, frames, exhaust pipes and other parts to provide strength and lightness. |

|

|

6.Shipbuilding: Used for hull structures, cabins, etc., with good corrosion resistance and strength. |

|

|

7.Electric power industry: used for brackets, pipelines, etc. of power equipment, which can withstand high temperature and high pressure environment. |

|

|

8.Furniture manufacturing: Used to make modern furniture, such as tables, chairs, etc., which are beautiful and practical. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

Product Display

Production process

.Raw Material Selection

The journey of creating seamless square tubes begins with the careful selection of raw materials. We source only the highest-grade steel and alloys, ensuring that our tubes possess the necessary mechanical properties for their intended applications. Our commitment to quality starts here, as we understand that the foundation of a superior product lies in the materials used.

.Heating and Forming

Once the raw materials are selected, they undergo a heating process that prepares them for forming. The steel is heated to a specific temperature, allowing it to become malleable. This step is crucial, as it ensures that the material can be shaped into a seamless tube without compromising its structural integrity. Our advanced heating technology allows for precise temperature control, resulting in consistent quality throughout the production process.

.Piercing

The next step in our seamless square tube production process is the piercing of the heated billet. This is a critical phase where the solid billet is transformed into a hollow tube. Using specialized piercing mills, we create a central hole in the heated material, which serves as the foundation for the subsequent forming process. Our piercing technology is designed to minimize defects and ensure uniformity in the tube’s dimensions.

.Elongation and Forming

Following the piercing process, the hollow tube undergoes elongation and forming. This step involves passing the pierced billet through a series of rollers that gradually shape it into a square cross-section. Our advanced forming techniques allow for precise control over the dimensions and wall thickness of the tube, ensuring that it meets the specific requirements of our clients. The result is a seamless square tube that is not only strong but also aesthetically pleasing.

.Heat Treatment

To enhance the mechanical properties of the seamless square tubes, we employ a heat treatment process. This step involves heating the formed tubes to a specific temperature and then cooling them at a controlled rate. Heat treatment improves the strength, ductility, and toughness of the material, making it suitable for demanding applications. Our state-of-the-art heat treatment facilities ensure that each batch of tubes receives the optimal treatment for maximum performance.

.Surface Finishing

Once the seamless square tubes have been formed and heat-treated, they undergo a thorough surface finishing process. This step is essential for removing any imperfections and ensuring a smooth, uniform surface. Our finishing techniques include shot blasting, pickling, and coating, which not only enhance the appearance of the tubes but also provide additional protection against corrosion and wear.

.Quality Control and Inspection

At the heart of our seamless square tube production process is a rigorous quality control and inspection protocol. Each tube is subjected to a series of tests to ensure that it meets the highest industry standards. We conduct dimensional inspections, mechanical property tests, and non-destructive testing to identify any potential defects. Our commitment to quality means that only the finest products make it to our clients.

.Packaging and Delivery

Once the seamless square tubes have passed our stringent quality checks, they are carefully packaged for delivery. We understand the importance of timely and safe delivery, and our logistics team works diligently to ensure that our products reach our clients in perfect condition. Whether you require a small batch or a large order, we are equipped to meet your needs efficiently.