01

Durable 7075 Aluminum Bar for Machining

Grade 7075 Bar Sizes & Specifications

|

gRADE |

cONDITION |

SHAPE |

TEMPER |

SIZE RANGE |

SPECIFICATION |

|

7075 |

Cold Finished |

Rounds | T6 |

3/8" |

AMS 4122/ ASTM B-211 |

|

T651 |

1/2" - 8" |

AMS 4123 / ASTM B-211 |

|||

|

T7351 |

3/4" - 6-1/2" |

AMS 4124 / ASTM B-211 |

|||

|

Squares |

T651 |

3/4" - 2-1/2" |

AMS 4123 / ASTM B-211 |

||

|

T7351 |

1-1/2" - 3" |

AMS 4124 / ASTM B-211 |

Grade 7075 Bar Typical Mechanical Properties (Not For Design)

|

grade |

temper |

tensile- ksi |

yield- ksi |

elongation-% |

brinell hardness |

|

7075 |

T651 |

83 |

73 |

11 |

150 |

|

T7351 |

74 |

63 |

14 |

130 |

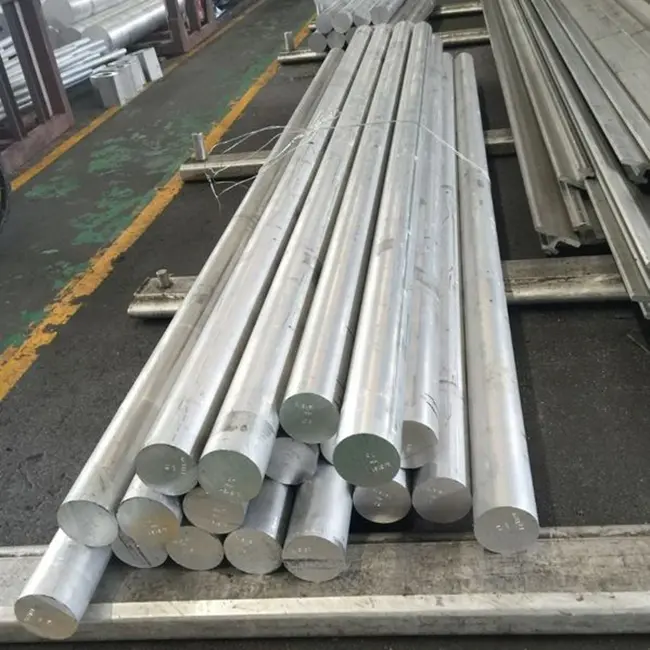

Product Display

Chemical Composition

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others: Each |

Others: Total |

Al: Min. |

|

3A21 |

0.60 |

0.70 |

0.20 |

1.0-1.6 |

0.05 |

- |

0.15 |

0.1-0.2 |

- |

- |

Margin |

Mechanical Properties

| Tensile Strength (MPa) | Yield Strength (MPa) | Hardness HB | Elongation Rate (%) |

| 89.6 | 34 | 23 | 15-28 |

Physical Performance

| Density | Melting Point | Modulus of Elasticity | Thermal Conductivity |

| 2.71 Kg/m³ | 643-675.2 °C | 68.9 GPa | 222 W/m.K |

Annealing State

|

Brand |

Annealing State |

|

1xxx: 1050, 1050A, 1060, 1100 |

O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

|

3xxx: 3003, 3004, 3005, 3105 |

|

|

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 |

O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

|

6xxx: 6061, 6082 |

T4, T6, T451, T651 |

|

2xxx: 2024 |

T3, T351, T4 |

|

7xxx: 7075 |

T6, T651 |