DIN 17100 ST37/ST12/ST14/ST52 Carbon Steel Coil

specification

| Product Name | DIN 17100 ST37/ST12/ST14/ST52 Carbon Steel Coil |

| Standard | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Thickness | Hot Rolling: 2.75mm-100mm Cold Rolling: 0.2mm-3mm |

| Width | 45mm-2200mm |

| Production Process | Hot Rolling, Cold Rolling |

| Error | ±1% |

| Certification | ISO 9001 ,CE,API |

| Surface treatment | Ordinary, Wire Drawing, Laminated Film |

| Country of origin | China |

| Main Applications | Building Structure、Bridges、Mechanical manufacturing、Shipbuilding、Automobile Industry、Pipelines and Tanks、Furniture and Equipment |

| Package | Bundling packaging、Anti-rust treatment、Wooden Pallet or Steel Pallet、Plastic film wrapping、Containerized shipping、Identification and labeling |

| Payment Term | TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

| After-sales service | 1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

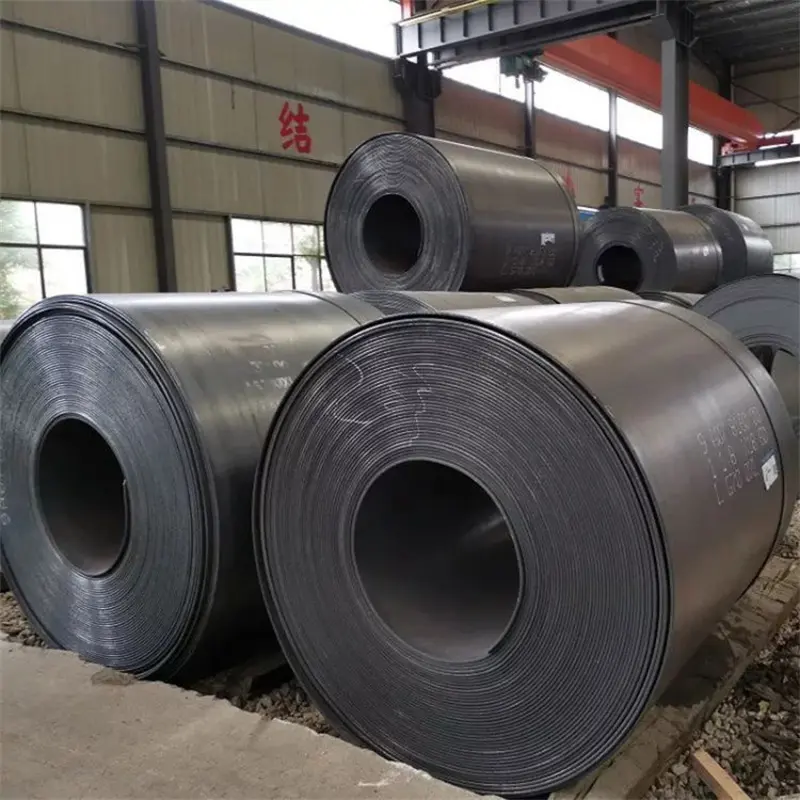

Product Display

Chemical Composition

|

Brand |

C |

P |

S |

N |

||||

|

≤ 16mm |

16-32mm |

32-40mm |

40-63mm |

63-100mm |

||||

|

St37-2 |

0.17 |

0.20 |

0.20 |

0.20 |

0.20 |

0.050 |

0.050 |

0.009 |

|

USt37-2 |

0.17 |

0.20 |

0.20 |

0.20 |

0.20 |

0.050 |

0.050 |

0.007 |

|

RSt37-2 |

0.17 |

0.17 |

0.17 |

0.20 |

0.20 |

0.050 |

0.050 |

0.009 |

|

St37-3 |

0.17 |

0.17 |

0.17 |

0.17 |

0.17 |

0.040 |

0.040 |

- |

|

St52-3 |

0.204 |

0.204 |

0.22 |

0.22 |

0.22 |

0.040 |

0.040 |

- |

|

ST12 Chemical Elements |

C |

Mn |

P |

S |

Al |

|

Percentage |

≤ 0.10 |

≤ 0.50 |

≤ 0.035 |

≤ 0.035 |

≥ 0.020 |

|

Steel grade |

Chemical Composition % |

|||||

|

C |

Mn |

p |

S |

Alta |

Ti b |

|

|

DC04 (St14, St15) |

≤ 0.08 |

≤ 0.40 |

≤ 0.025 |

≤ 0.020 |

≥ 0.020 |

- |

Mechanical Properties

|

Brand |

Tensile Strength |

Yield Strength |

|||||

|

< 3 mm |

3-100 mm |

≤ 16 mm |

16-40 mm |

40-63 mm |

63-80 mm |

80-100 mm |

|

|

St37-2 |

360-510 |

340-470 |

235 |

225 |

215 |

205 |

195 |

|

USt37-2 |

- |

- |

- |

- |

- |

- |

- |

|

RSt37-2 |

- |

- |

235 |

225 |

215 |

215 |

215 |

|

St37-3 |

- |

- |

- |

- |

- |

- |

- |

|

St52-3 |

510-680 |

490-630 |

365 |

355 |

345 |

335 |

325 |

|

ST12 Mechanical Properties |

Tensile Strength |

Yield Strength |

Elongation |

|

270-410 MPa |

≤ 280 MPa |

≥ 28 % |

|

Steel grade |

Yield Strength a MPa |

Tensile Strength Mpa ≥ |

After Breakage Percent Elongation (L o =80mm, b=20mm) % ≥ |

r b,c ≥ |

n b, c ≥ |

|||

|

Nominal Thickness mm |

||||||||

|

< 0.70 |

0.70-< 1.0 |

1.0-< 1.6 |

≥ 1.6 |

|||||

|

DC04 (St14, St15) |

120-210 |

270 |

36 |

38 |

39 |

40 |

1.5 |

0.18 |