-

Phone

-

E-mail

-

Whatsapp

The machinery steel industry is experiencing significant advancements that are redefining its landscape. According to a recent report by MarketsandMarkets, the machinery steel market is projected to grow at a CAGR of 5.4% from 2022 to 2027. This growth is driven by ongoing innovations in material properties and manufacturing processes.

Experts, like Dr. Samuel Ling, a leading authority in machinery steel development, stated, "The future of machinery steel relies on how we adapt to changing demands." This statement underscores the industry's need for continuous innovation. Companies are now focusing on enhancing strength while reducing weight. Innovations such as high-strength low-alloy steels are being adopted widely.

However, challenges remain. The environmental impact of steel production is under scrutiny. Reports indicate that the steel industry is responsible for about 8% of global CO2 emissions. Balancing innovation with sustainability is crucial. As the machinery steel sector evolves, it must confront these issues head-on to thrive.

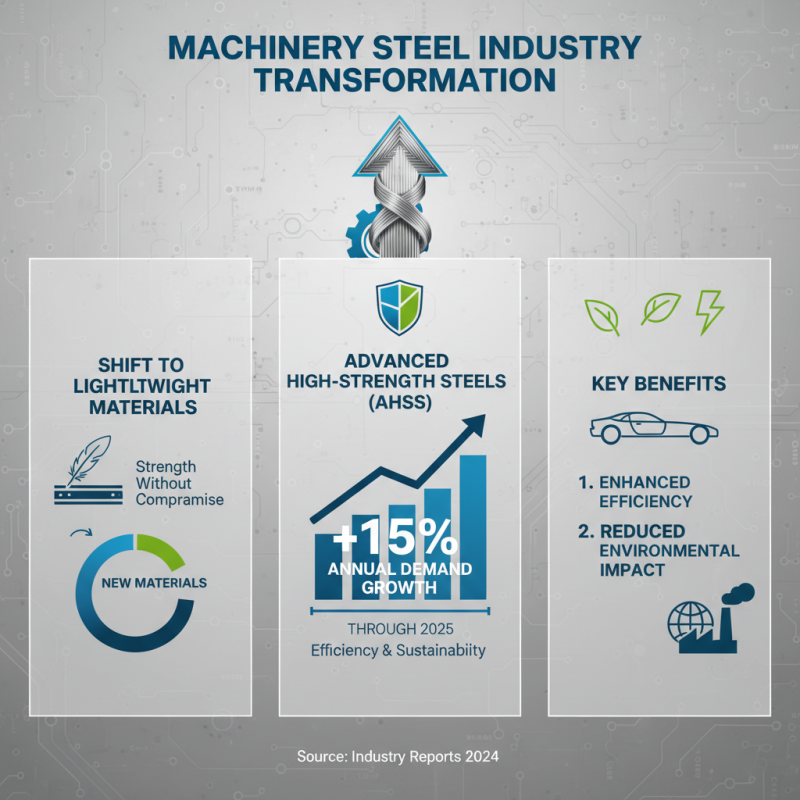

The machinery steel industry is undergoing a transformative phase. Emerging trends show a shift towards lightweight materials that do not compromise strength. Reports indicate that demand for advanced high-strength steels (AHSS) could increase by 15% annually through 2025. This demand stems from the need for efficiency and sustainability in manufacturing.

Recycling and eco-friendly practices are gaining traction. A survey by a leading industry body reveals that 70% of manufacturers prioritize sustainability. They are investing in technologies that repurpose steel waste. Innovations such as microalloying and advanced coating techniques are becoming more common. These processes enhance material properties and reduce environmental impact.

Software-driven design is another noteworthy trend. Digital twins and AI are helping engineers predict steel performance. Recent studies highlight that companies using these tools improved their design efficiency by 20%. However, challenges remain. Not all industries are adapting quickly. Some traditional processes are resistant to change, which could hinder future advancements. The balance between innovation and practical application is crucial for sustained growth.

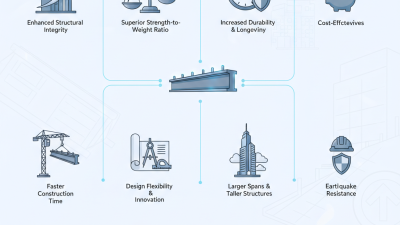

The machinery steel industry is evolving rapidly. Innovations in key technologies are shaping its future. Advanced alloying techniques enhance strength and durability. This results in longer-lasting machines and structures. Developments in manufacturing processes also play a crucial role. New methods reduce waste and lower production costs.

3D printing technology has emerged as a game changer. It allows for quicker prototyping and design iterations. However, challenges remain in scalability and material quality. Cyber-physical systems integrate machinery with digital technologies. This connection improves optimization but raises security concerns. Manufacturers must navigate these risks carefully.

Sustainability is increasingly important in the industry. Alternative materials are being explored to reduce environmental impact. However, integrating these options can be complex. The balance between innovation and practicality is crucial. Industry players must reflect on their processes and adapt intelligently.

Advanced materials are transforming the machinery steel sector. Innovations in steel composition are enhancing durability and strength. These materials are lighter yet stronger, allowing for more efficient machinery design.

The impact of these advanced materials is significant. For example, high-strength low-alloy steels improve fatigue resistance. This means machinery can handle more stress over time. It’s crucial to note that integrating new materials is challenging. Many companies struggle to adapt their manufacturing processes. They often face unexpected issues during production, which can lead to delays and increased costs.

Research is ongoing, and the future looks promising. Enhanced coatings and composites are emerging, providing better corrosion resistance. However, the full benefits of these innovations are not yet realized. Companies must take the time to evaluate their choices. The transition to advanced materials requires careful consideration and planning. Ultimately, the goal is better performance and safety in machinery steel applications.

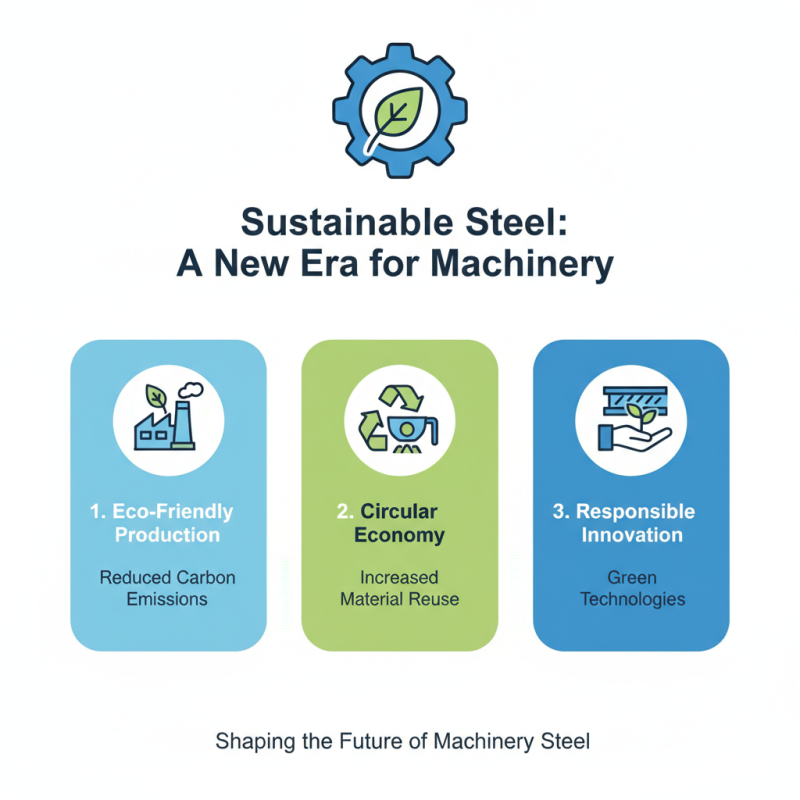

The machinery steel industry is undergoing significant change, focusing on sustainability practices. Steel production often faces criticism for its environmental impact. However, companies are making strides to address these concerns.

Recycling scrap metal is one major initiative. It reduces waste and conserves resources. Innovative technologies allow for better metal recovery methods. Some plants are now powered by renewable energy sources. This shift not only lowers carbon footprints but also drives efficiency.

Tip: Implementing green practices can enhance a company's reputation.

Another area of focus is reducing water usage. Traditional steel production requires vast amounts of water. New techniques challenge this norm, aiming for a closed-loop system. Companies are exploring alternative cooling methods that consume less water. Yet, these innovations come with their own challenges, including initial costs and adaptation periods.

Tip: Invest in employee training for sustainable practices.

As the industry evolves, balancing profitability and sustainability remains critical. Companies must reflect on their methods and strive for continuous improvement. Adopting these practices not only safeguards the environment but also promotes long-term growth. The journey is complex, and the outcomes may vary, but the commitment to change is essential.

The next decade is set to revolutionize machinery steel innovation. Advances in technology are driving this change. New manufacturing processes are emerging, focusing on higher efficiency and sustainability. Think about additive manufacturing, which allows for complex designs with less material waste. Innovations like this could reshape the entire industry landscape.

Yet, challenges remain. The transition to greener production methods is not straightforward. Many companies struggle with the cost of new technologies. There is a need for better understanding and investment in research. These innovations must be balanced with practicality. Developing alloys that enhance durability can also be tricky. How do we ensure optimal performance while minimizing environmental impact?

The future of machinery steel hinges on collaboration. Engineers, researchers, and manufacturers must work together. Open dialogue can lead to breakthroughs. Embracing failure as a part of the innovation process is crucial. Each setback is a chance for learning. Only through collective effort and a willingness to adapt can the industry truly thrive in the coming years.

| Innovation | Description | Impact on Industry | Projected Growth Rate (%) |

|---|---|---|---|

| High-Strength Steel Alloys | New alloys providing improved strength and durability. | Enhanced performance in heavy machinery. | 5% |

| Corrosion-Resistant Coatings | Advanced coatings that extend the lifespan of machinery. | Reduced maintenance costs and downtime. | 6% |

| 3D Printed Components | Using additive manufacturing for complex steel parts. | Lower material waste and faster prototyping. | 8% |

| Smart Steel | Steel embedded with sensors for real-time monitoring. | Improved predictive maintenance and monitoring. | 7% |

| Recycled Steel Technologies | Innovative processes to recycle steel efficiently. | Sustainability and reduced carbon footprint. | 10% |