-

Phone

-

E-mail

-

Whatsapp

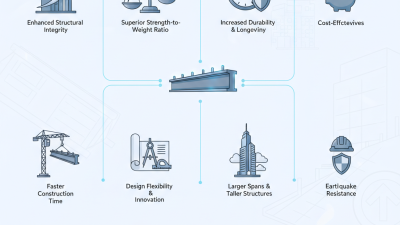

Square Tube Steel has become a popular choice in construction projects. Its unique design offers numerous advantages. This material stands out for its strength and versatility.

Using Square Tube Steel enhances structural integrity. It can withstand heavy loads while minimizing the need for additional supports. This makes it ideal for buildings and bridges. The uniform shape allows for easier fabrication and assembly. Crews can work efficiently, reducing labor costs.

Moreover, Square Tube Steel is both lightweight and durable. It resists corrosion better than many alternatives. This longevity can lead to long-term savings. However, it's essential to consider the initial investment costs. While beneficial, the material's price may deter some projects. Understanding these pros and cons is crucial for effective decision-making.

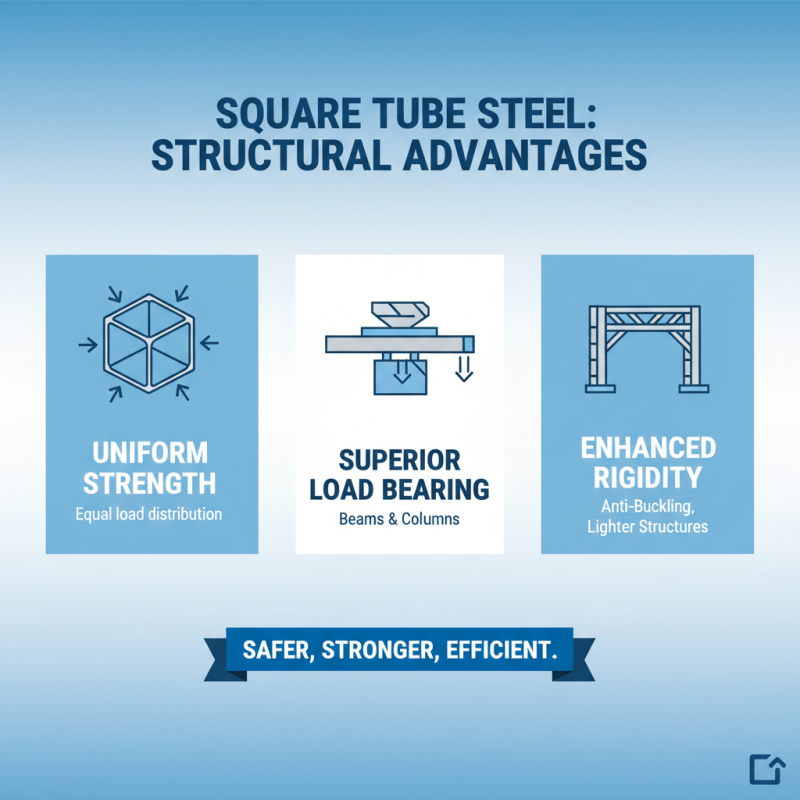

Square tube steel offers unique advantages in load-bearing structures. Its shape provides uniform strength across all sides. This design allows for better load distribution, making it ideal for beams and columns. The rigidity of square tubes reduces the risk of buckling under heavy loads. In many cases, this can lead to lighter structures without compromising safety.

Another benefit is the ease of assembly. Square tubes are easier to connect than round ones. Their flat surfaces provide better welding points. This can cut down on construction time and labor costs. Additionally, square tube steel has a smaller footprint compared to other shapes, freeing up more space for insulation or electrical work.

However, not every project benefits from square tube steel. It can be heavier than other materials. This needs careful consideration in certain designs. Sometimes, the cost may rise if not sourced properly. Yet, for many load-bearing applications, the benefits far outweigh these challenges.

When it comes to construction, square tube steel proves to be a cost-effective option. Its uniform shape allows for stable connections and easier assembly. This translates to reduced labor costs. Fewer adjustments are needed during installation, saving valuable time on the project.

Moreover, square tube steel is lightweight yet strong. This characteristic can lead to lower transportation costs. The material occupies less space, allowing for more efficient loading and unloading procedures. However, it’s important to note that selecting the right thickness is crucial. Using steel that is too thin may compromise structural integrity.

Emphasizing durability, square tube steel is resistant to various environmental factors. This longevity can result in reduced maintenance expenses over a building's lifespan. Interestingly, some projects still overlook the need for proper protective treatments. This oversight can lead to premature wear. Additionally, the initial cost savings might become a hidden expense later if proper care is not taken.

Square tube steel offers remarkable design flexibility in construction. Its uniform shape allows for easy integration into various architectural styles. Whether it’s for residential or commercial structures, this material adapts well. The squared edges facilitate precision cuts and connections. This ensures tight joints, which enhance the overall strength. The ability to precisely weld or connect sections expands the creative possibilities.

Considerations must be made when using square tube steel. While it's versatile, not every design requires its properties. Some projects may benefit from other shapes or materials. Additionally, the weight of square tube steel can pose challenges. Heavier sections require stronger foundations. A design might look appealing on paper but may need adjustments during the build. Flexibility does not mean one-size-fits-all. Each project demands careful planning to avoid potential setbacks.

Square tube steel components offer remarkable durability and longevity in construction. These steel structures can withstand significant stress and strain. They resist deformation and retain their shape under heavy loads. This makes them a popular choice for various applications, from building frames to structural supports. Many construction professionals appreciate this strength.

Square tube steel is also resistant to environmental challenges. It can endure exposure to moisture, chemicals, and temperature fluctuations. This resistance minimizes rust and corrosion, extending the life of the material. Projects using square tube steel face fewer maintenance issues over time. However, it's essential to ensure proper installation techniques to maximize these benefits. Poor welding or misalignment could lead to unforeseen problems.

While square tube steel is incredibly strong, improper use can lead to failures. It’s crucial to consider load capacities and potential weaknesses in designs. Regular inspections can help catch issues before they escalate. Understanding these potential pitfalls adds to the successful use of square tube steel in construction. The material's attributes encourage a long-lasting and reliable outcome when used correctly.

Sustainability is a key focus in modern building design. Square tube steel offers several sustainable benefits. Its durability contributes to longer lifespans of structures. This reduces the frequency of replacements. Less material used in repairs means lower resource consumption.

Using recycled materials is an eco-friendly choice. Square tube steel can often be made from recycled steel. This choice decreases the environmental footprint. Each ton of recycled steel saves energy and reduces waste. Construction methods using square tubes can also minimize site disturbance.

Here are some tips to maximize sustainability with square tube steel. Consider using it for load-bearing structures. Evaluate the design to use minimal steel while maintaining strength. Explore connections that require less material, as they can simplify the construction process. Reflect on your choices; sometimes, less is more in design efficiency.

| Benefit | Description | Sustainability Impact |

|---|---|---|

| High Strength-to-Weight Ratio | Square tube steel provides excellent structural support while minimizing weight. | Reduces material usage and enhances energy efficiency in construction. |

| Versatility | Can be utilized in a variety of applications, from framing to supports. | Supports a wide range of eco-friendly designs and sustainable solutions. |

| Recyclability | Steel is highly recyclable, allowing for reuse of materials. | Contributes to reduced waste in landfills and preservation of natural resources. |

| Durability | Resistant to corrosion and wear, leading to longer lifespan. | Decreases the need for frequent replacements and repairs. |

| Cost-Effective | Lower long-term costs due to longevity and reduced maintenance. | Promotes more efficient use of resources over the building's life cycle. |

| Aesthetic Appeal | Can be finished in various styles and colors for design flexibility. | Encourages innovative design approaches in sustainable architecture. |

| Fire Resistance | Steel materials resist fire damage better than many alternatives. | Enhances the safety and resilience of buildings in fire-prone areas. |

| Energy Efficiency | Square tubes can improve insulation properties when designed correctly. | Reduces energy consumption and increases comfort in buildings. |

| Safety | The structural integrity of square tubes leads to safer constructions. | Minimizes risk of structural failures, protecting occupants and property. |

| Quick Installation | Pre-engineered and prefabricated options allow for faster builds. | Minimizes construction waste and reduces onsite environmental impact. |