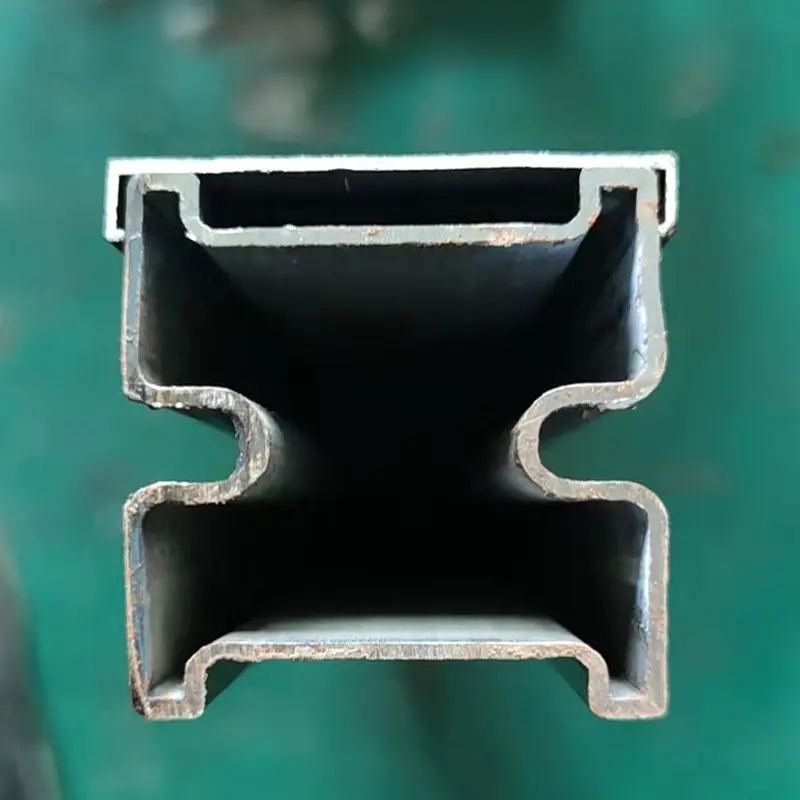

A36, S355JR, Q235 special-shaped pipe

specification

|

Product Name |

A36, S355JR, Q235 special-shaped pipe |

|

Standard |

GB/T 6728-2002、ASTM A500、EN 10219、EN 10210、JIS G 3466、JIS G 3444 |

|

Material |

Q235、Q345、Q195、A36、A500、A53、S235、S355、S275、SS400、SM490 |

|

Outer diameter range |

The outer diameter can range from a few millimeters to hundreds of millimeters. Common outer diameters are 10mm, 20mm, 50mm, 100mm, 200mm, 300mm, etc. |

|

Thickness range |

Common wall thickness ranges from 1mm to 20mm, depending on the pipe’s outer diameter and design requirements. |

|

Length range |

Common lengths are 6 meters, 12 meters, etc. They can also be cut according to project requirements. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Hot dip galvanizing, spraying, electroplating, phosphating, pickling and passivation, polishing, coating |

|

Country of origin |

China |

|

Main Applications |

1.Decorative Application: In architectural decoration, carbon steel profiled tubes can be used for railings, handrails, etc. |

|

2.Equipment frame: It serves as a frame structure in mechanical equipment to provide support and stability. |

|

|

3.Exhaust system: Used for automobile exhaust pipes, high temperature and corrosion resistance. |

|

|

4.Transmission Pipelines: Pipelines used for oil and gas transmission, capable of withstanding high pressure and corrosive environments. |

|

|

5.Storage tanks and equipment: Equipment used to store and process media such as oil and natural gas. |

|

|

6.Piping system: Used as a transport pipeline in the piping system of a chemical plant. |

|

|

7.Transmission tower: In the structure of the transmission tower, it is used to support the pipeline. |

|

|

8.Pipeline system: Used as a transport pipeline in the ship’s pipeline system. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

Product Display

Why use carbon steel special-shaped pipes

1.Excellent mechanical properties

Carbon steel profiled pipes have high strength and toughness, can withstand greater pressure and load, and are suitable for load-bearing structures and heavy-duty applications.

2.Good processability

Carbon steel is easy to cut, weld and form, and can be customized in various sizes and shapes according to specific needs to meet different design requirements.

3.Cost-effectiveness

Compared with other materials (such as stainless steel, aluminum alloy, etc.), carbon steel has a lower cost and is suitable for large-scale production and application, which can effectively reduce project costs.

4.Wide range of applications

Carbon steel special-shaped pipes are widely used in many industries such as construction, machinery manufacturing, automobiles, oil and gas, and chemicals, and have strong adaptability.

5.Abrasion resistance and durability

Carbon steel profiled pipes have good wear resistance in certain applications and can be used for a long time in harsh environments.

6.Various surface treatments available

Carbon steel special-shaped pipes can be subjected to a variety of surface treatments such as hot-dip galvanizing, spraying, phosphating, etc. to enhance their corrosion resistance and aesthetics and adapt to different use environments.

7.Lightweight design

The design of the special-shaped tube can optimize the use of materials and achieve lightweight while ensuring strength, which is suitable for the needs of modern engineering.

8.Environmental

Carbon steel material can be recycled, which meets the requirements of sustainable development.

Production process

1.Raw material preparation

Material selection: Select appropriate carbon steel materials according to product requirements. Commonly used ones are Q235, Q345, etc.

Cutting: Cutting large coils or large blocks of steel into suitable sizes for subsequent processing.

2.Molding

Hot Rolling or Cold Rolling: Steel is processed into tubes by hot rolling or cold rolling process. Hot rolling is suitable for large diameter tubes, and cold rolling is suitable for small diameter tubes.

Special-shaped tube forming: Use special forming equipment (such as special-shaped tube forming machine) to process the steel tube into the required special-shaped section (such as rectangular, square, oval, etc.).

3.Welding

Welding process: For special-shaped pipes that need to be welded, use appropriate welding processes (such as arc welding, laser welding, etc.) to weld the edges of the pipes together to ensure welding quality.

Welding inspection: Perform non-destructive testing (such as ultrasonic testing, X-ray testing, etc.) on welded joints to ensure that the welding quality meets the standards.

4.Heat treatment

Annealing treatment: Annealing treatment is performed on the special-shaped pipe after welding to eliminate internal stress and improve the toughness and plasticity of the pipe.

Normalizing: In some cases, normalizing may be necessary to improve the mechanical properties of the material.

5.Surface treatment

Cleaning: Remove oxides, oil stains and impurities from the pipe surface.

Surface treatment: Hot-dip galvanizing, spraying, phosphating and other surface treatments can be performed as required to improve corrosion resistance and aesthetics.

6.Cutting and finished product inspection

Cutting: Cut the special-shaped tube into the length required by the customer.

Finished product inspection: Inspect the finished product in terms of size, appearance, performance, etc. to ensure that it meets customer requirements and relevant standards.

7.Packaging and Shipping

Packaging: The finished products are packaged according to transportation requirements to ensure that they are not damaged during transportation.

Shipping: Qualified products will be shipped to the customer’s designated location.