430 Stainless coil: decor & appliance use

specification

|

Product Name |

430 stainless steel coil |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Thickness |

0.3mm-200mm |

|

Width |

610mm-2000mm |

|

Length |

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

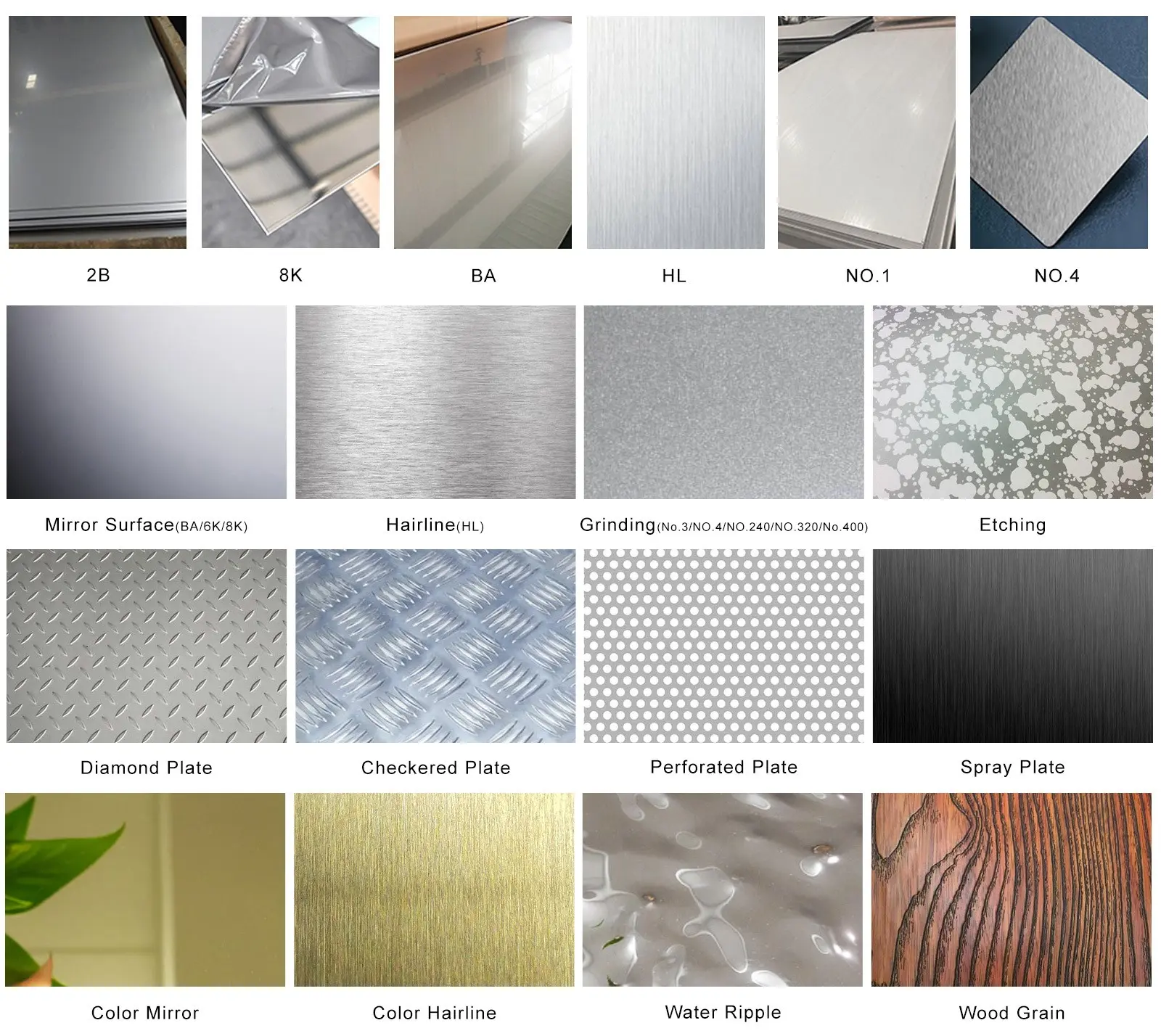

Surface treatment |

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

|

Country of origin |

China |

|

Main Applications |

Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

|

Package |

Bundling packaging、Wooden box packaging、Plastic film packaging、Pallet packaging、Anti-rust oil coating、Bubble film packaging |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

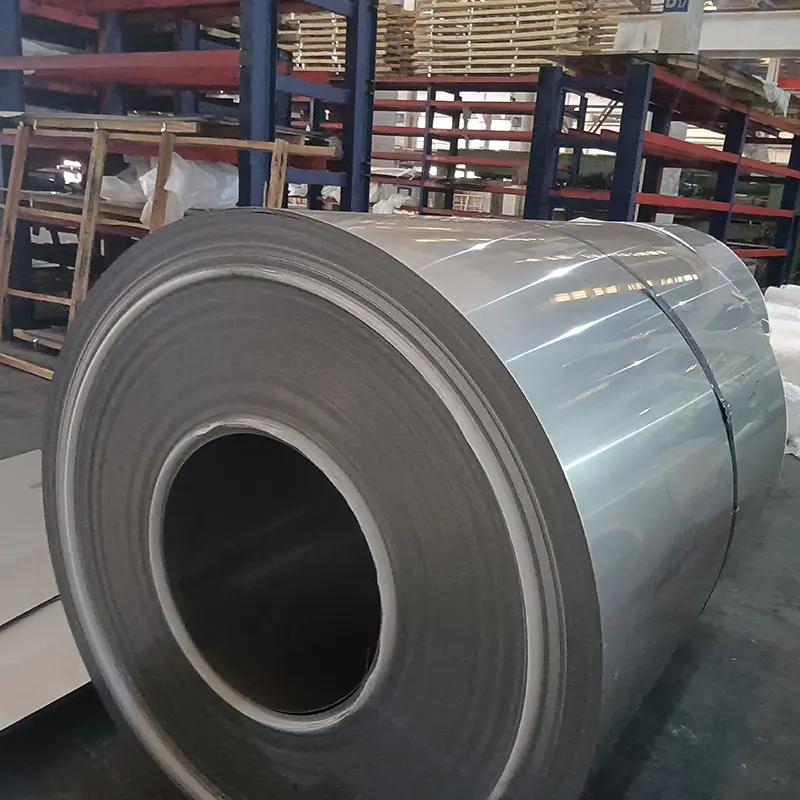

Product Display

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.12 |

≤ 1.0 |

≤ 1.0 |

16.0~18.0 |

≥ 0.75 |

≤ 0.03 |

≤ 0.04 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥634 |

≥440 |

≥ 20 |

Annealing≤ 223HB; quenching and tempering ≥ 192HB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.70 |

200 |

10.4 |

23.9 |

360 |

Surface Selection