304L high quality stainless steel pipe

specification

|

Product Name |

304L stainless steel pipe |

|

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

|

Outer diameter |

Round Pipe |

4mm-200mm |

|

Square Pipe |

10*10mm-100*100mm |

|

|

Rectangular Pipe |

10*20mm-50*100mm |

|

|

Wall Thickness |

0.6mm-6.0mm |

|

|

Length range |

1-6 meters, Length can be customized |

|

|

Error |

±1% |

|

|

Certification |

ISO 9001 ,CE,API |

|

|

Surface treatment |

Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. |

|

|

Country of origin |

China |

|

|

Main Applications |

1.Chemical industry: 304L stainless steel pipes are often used in chemical reactors, storage tanks, pipelines and other equipment, and can resist corrosion from a variety of chemical media. |

|

|

2.Food and Beverage Industry: Due to its excellent hygienic properties, 304L stainless steel pipes are widely used in pipelines and equipment in food processing, beverage production and pharmaceutical industries. |

||

|

3.Oil and gas industry: In the extraction, transportation and processing of oil and gas, 304L stainless steel pipes are also widely used and can withstand high temperature and high pressure environments. |

||

|

4.Construction and Decoration: 304L stainless steel pipes are used in the construction industry for structural support, railings, decorative elements, etc., and are favored for their beauty and durability. |

||

|

5.Marine Engineering: Due to its excellent corrosion resistance, 304L stainless steel pipe is suitable for various equipment and pipelines in the marine environment. |

||

|

6.Heat Exchanger: 304L stainless steel pipes are often used in heat exchangers due to their good thermal conductivity and corrosion resistance. |

||

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

|

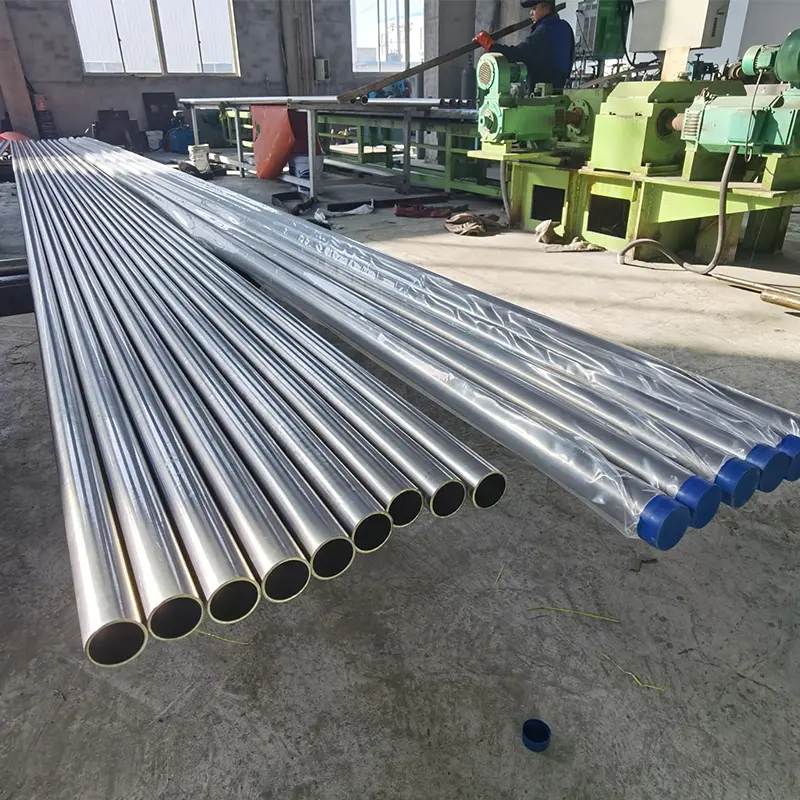

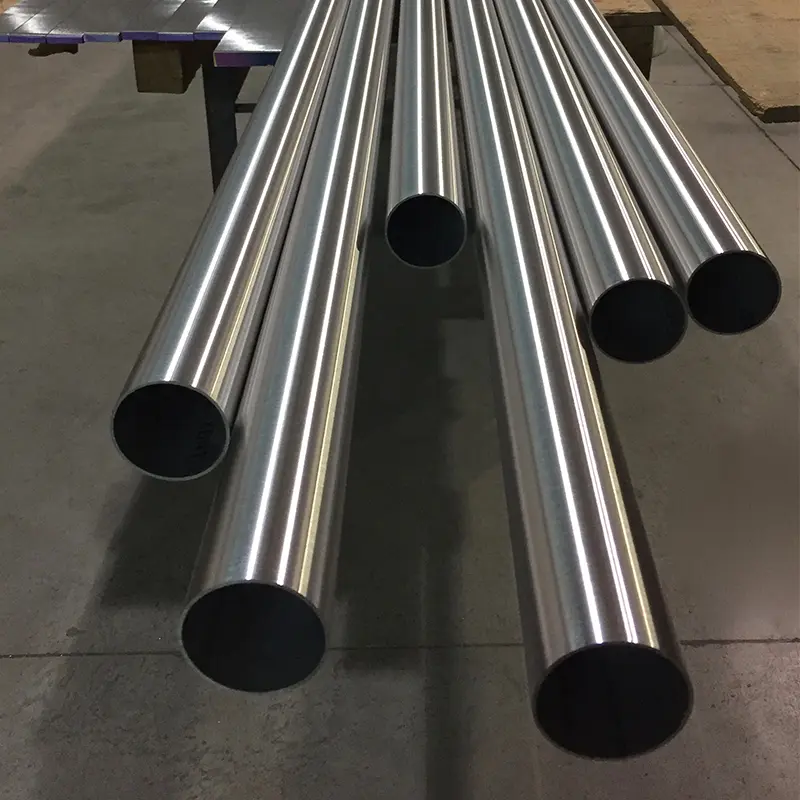

Product Display

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.03 |

≤1.0 |

≤ 2.0 |

18.0~20.0 |

8.0~12.0 |

≤ 0.03 |

≤ 0.035 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥520 |

≥ 205 |

≥ 40 |

≤ 187HB ;≤ 90HRB;≤ 200HV |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

8.03 |

193 |

16.9 |

16.2 |

72 |

Production process

Raw material preparation:

Choose the right 304L stainless steel alloy material. Usually, raw materials such as iron ore, nickel, and chromium are melted in a smelting furnace to make stainless steel billets.

Casting:

The molten metal is cast into an ingot or block, which is then cooled to form a rough metal shape.

Hot rolled or cold rolled:

Hot rolling: After the ingot is heated to a certain temperature, it is rolled through a rolling mill to form a preliminary tube billet.

Cold rolling: The tube is further rolled at room temperature to improve its strength and surface finish.

Tube forming:

The rolled tube is formed, usually by extrusion, welding or seamless process. Seamless tubes are made by piercing and expanding, while welded tubes are made by welding metal strips into a tube shape.

Heat treatment:

Heat treatment is performed on the formed stainless steel pipe to eliminate internal stress and improve its mechanical properties and corrosion resistance. Common heat treatment methods include annealing.

Cooling and cleaning:

After heat treatment, the pipe needs to be cooled and pickled or other cleaning methods to remove surface oxides and impurities to improve surface quality.

Inspection and testing:

Carry out various inspections on 304L stainless steel pipes, including dimensional measurement, appearance inspection, mechanical property testing and chemical composition analysis, etc., to ensure that the products meet standards and customer requirements.

Surface treatment:

According to customer needs, 304L stainless steel pipes can be surface treated, such as polishing, sandblasting or coating, to improve its appearance and corrosion resistance.

Packaging and Shipping:

Finally, the qualified 304L stainless steel pipes are packaged and ready to be shipped to customers.