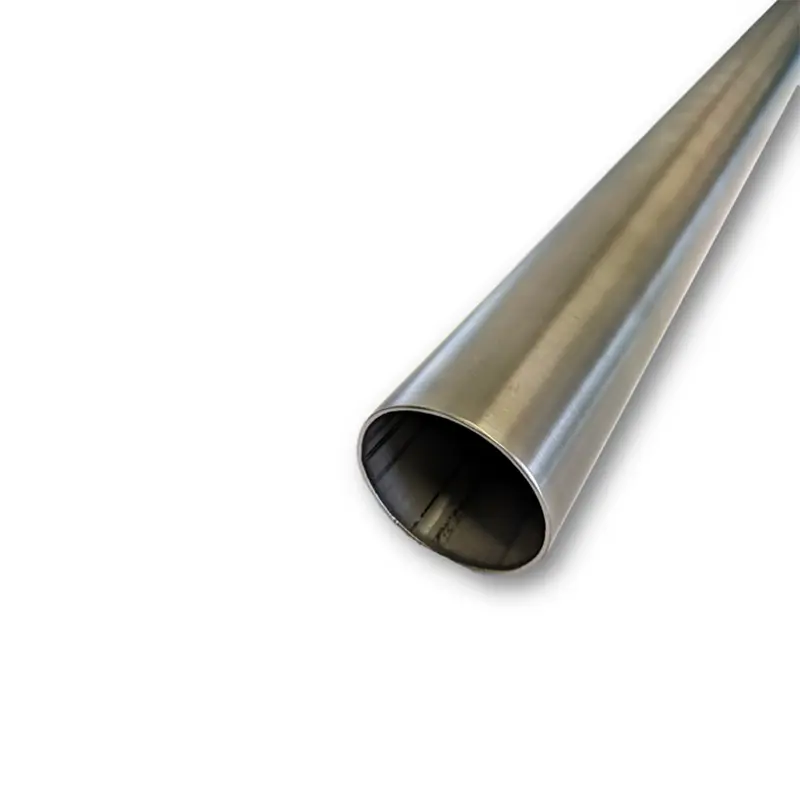

304 seamless, strong, high - use, corrosion - proof

specification

|

Product Name |

304 seamless steel pipe |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

ASTM A240/A240M - 304、DIN EN 10088-2 - 1.4301、JIS G4305 - SUS304、ГОСТ 5632-72 - 08Х18Н10 |

|

Outer diameter range |

Capillary tube: The outer diameter is generally between 0.4mm-40mm Conventional round tube: The outer diameter usually starts from about 6mm Large diameter thick wall tube: Some large diameter thick wall 304 stainless steel seamless steel tubes with special requirements can even have an outer diameter of more than 1220mm |

|

Thickness range |

Capillary tube: wall thickness is generally between 0.15mm-2mm Conventional round tube: usually starts from 0.5mm Thick wall tube: wall thickness is above 20mm |

|

Length range |

Customized length according to customer's special requirements. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

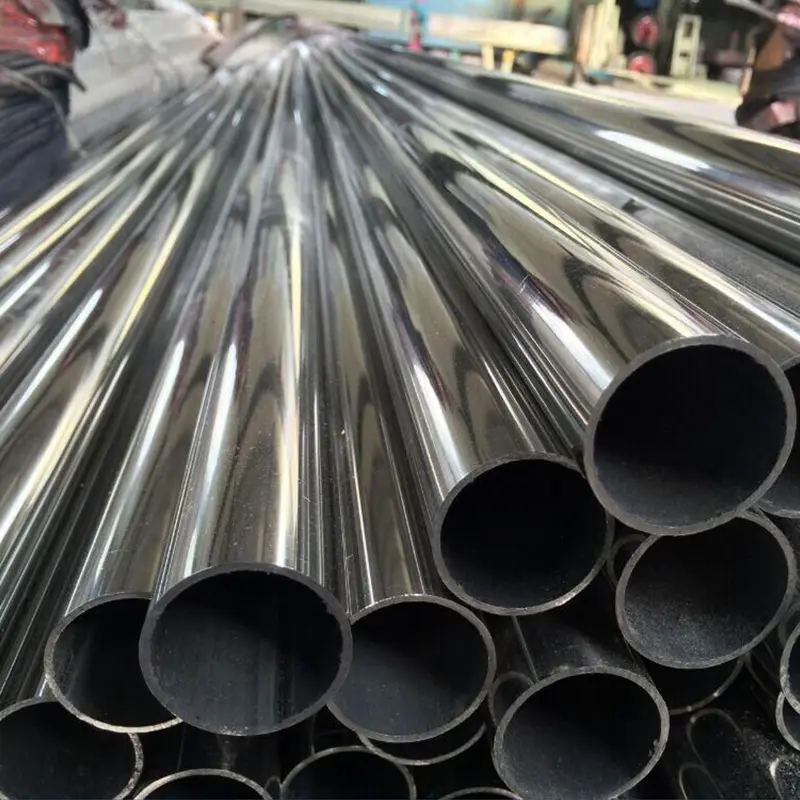

Surface treatment |

Pickling and passivation, mechanical polishing, electrolytic polishing, sandblasting, painting, electroplating |

|

Country of origin |

China |

|

Main Applications |

1.Oil and gas industry: Pipeline systems used in the extraction, transportation and processing of oil and gas. Its corrosion resistance can resist the corrosive media in oil and gas and ensure the long-term stable operation of the pipeline. |

|

2.Chemical industry: widely used in storage tanks, pipelines, heat exchangers, etc. in chemical equipment, and can withstand the erosion of various acid, alkali, salt and other chemical media to ensure the safety and stability of chemical production |

|

|

3.Power industry: Suitable for manufacturing pipes for boilers, heat exchangers, condensers and other equipment. It can maintain good performance in high temperature and high pressure working environments to meet the needs of power production. |

|

|

4.Automobile industry: used in exhaust systems, brake systems and other parts in automobile manufacturing |

|

|

5.Food industry: can be used for food processing, storage and transportation equipment |

|

|

6.Medical device field: used to manufacture infusion pipes, stents, surgical instruments, implants, etc. in medical devices |

|

|

7.Building structure: It can be used for handrails, railings, doors and windows and other decorative products in buildings. Its aesthetics, corrosion resistance and strength make it an ideal building material |

|

|

8.Transportation: In addition to the automotive industry, it can also be used to manufacture some parts in the fields of ships, rail transportation, etc. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

Product Display

Production process

Billet preparation

Material selection: Select high-quality 304 stainless steel billets to ensure that their chemical composition meets relevant standards, such as containing about 18% chromium, 8% nickel and other major alloying elements to ensure the corrosion resistance and other properties of the steel pipe.

Inspection: Strict inspection of the billets, including appearance inspection to check whether there are defects such as cracks and inclusions on the surface; size measurement to ensure that the diameter, length and other dimensions of the billets meet production requirements; chemical composition analysis to verify whether the content of alloy elements meets the standards.

Pretreatment: Grind and pickle the billets to remove impurities such as oxide scale and rust on the surface, so that the billet surface is smooth and flat, providing a good foundation for subsequent processing.

Hot rolling process

Heating: Heat the pretreated billet to a suitable temperature range, generally around 1000℃-1200℃, to facilitate subsequent piercing and rolling operations.

Piercing: Use a piercing machine to pierce a hole in the center of the heated billet to form a hollow tube billet. During the piercing process, the parameters such as piercing speed and head pressure should be controlled to ensure the piercing quality and avoid problems such as cracks in the hole wall and eccentricity.

Rolling: The pierced tube billet is sent to the rolling mill for rolling. Through multiple rolling passes, the outer diameter and wall thickness of the tube billet are gradually reduced to achieve the required dimensional accuracy and surface quality. During the rolling process, factors such as rolling temperature, force and number of rolling passes should be strictly controlled to ensure the material properties and mechanical properties of the seamless pipe.

Sizing: The rolled steel pipe is sizing treated to further accurately adjust the outer diameter of the steel pipe to meet the product standard requirements. Sizing is usually performed on a sizing machine, and the outer diameter of the steel pipe is controlled by adjusting the spacing of the rollers.

Heat treatment

Purpose: Heat treatment of hot-rolled steel pipes is mainly to eliminate the residual stress generated by the steel pipe during the rolling process, improve the organizational structure, and improve the comprehensive performance of the steel pipe, such as strength, toughness, corrosion resistance, etc.

Process: Common heat treatment processes include annealing and normalizing. For 304 stainless steel seamless pipes, solid solution treatment is generally used, that is, the steel pipe is heated to about 1050℃-1150℃, kept warm for a period of time, and then quickly cooled to fully dissolve the carbide in the austenite, obtain a single-phase austenite structure, and improve the corrosion resistance and toughness of the steel pipe.

Surface treatment

Pickling: After hot rolling and heat treatment, there will be a layer of oxide scale and other impurities on the surface of the steel pipe, which needs to be pickled. Pickling usually uses acid (such as sulfuric acid, hydrochloric acid, etc.) to dissolve and remove the oxide scale and rust on the surface of the steel pipe, so that the surface of the steel pipe is restored to a smooth surface. After pickling, water washing is also required to remove the acid remaining on the surface of the steel pipe.

Ultrasonic cleaning: After pickling, the steel pipe may still have some tiny impurities and dirt. Ultrasonic cleaning technology is used to use the cavitation effect of ultrasonic waves in the liquid to generate a strong impact force to further remove the dirt and impurities on the surface of the steel pipe and improve the cleanliness of the steel pipe.

Cold processing

Cold rolling: The steel pipe after pickling and cleaning is cold rolled, and the steel pipe is squeezed by the rollers of the cold rolling mill to further reduce its outer diameter and wall thickness, while improving the dimensional accuracy and surface quality of the steel pipe. Cold rolling can make the steel pipe obtain better mechanical properties, such as higher strength and hardness.

Cold drawing: Cold drawing is to draw the steel pipe through a die to reduce the outer diameter and wall thickness of the steel pipe and increase its length. During the cold drawing process, the steel pipe is subjected to a large tensile force, its internal structure is denser, and the mechanical properties are further improved. Cold drawing and cold rolling processes can be used alone or in combination. The specific processing method is determined according to different product requirements.

Finishing and inspection

Straightening: After cold processing, the steel pipe may be bent and deformed, and straightening is required to make the straightness of the steel pipe meet the product standard requirements. Straightening is usually carried out on a straightening machine, and the steel pipe is straightened by applying a certain external force.

Cutting: According to customer requirements, the straightened steel pipe is cut into the required length size.

Non-destructive testing: Non-destructive testing technology, such as ultrasonic flaw detection and magnetic particle flaw detection, is used to detect the inside and surface of the steel pipe to check for defects such as cracks, pores, inclusions, etc., to ensure that the quality of the steel pipe meets the standard requirements.

Physical and chemical performance inspection: Physical and chemical performance inspection of steel pipes, including tensile tests, hardness tests, impact tests, chemical composition analysis, etc., to verify the mechanical properties and chemical properties of steel pipes. Whether the ingredients meet the relevant standards and customer requirements.

Packaging and warehousing

Packaging: The qualified steel pipes are packaged. The packaging method is determined according to the size, quantity and customer requirements of the steel pipes. Common packaging methods include bundling packaging and wooden box packaging to prevent the steel pipes from being damaged during transportation and storage.

Marking: Mark the product specifications, materials, production date, manufacturer and other information on the surface of the steel pipe or the packaging for easy identification and traceability.

Warehousing: Store the packaged steel pipes in the warehouse, store them according to specifications, materials, etc., take moisture-proof and rust-proof measures, and wait for shipment

Why choose us, our advantages

1. Procurement of high-quality raw materials: Our company always insists on purchasing high-quality raw materials from reliable suppliers and strictly controls the quality of raw materials. We have established long-term and stable cooperative relationships with many well-known suppliers of raw materials such as iron ore and coke, ensuring that each batch of raw materials used meets or even exceeds industry standards, laying a solid foundation for the production of high-quality steel.

2. Advanced production technology and equipment: We have a set of advanced production processes and modern production equipment, which enables us to accurately control key indicators such as the chemical composition, mechanical properties and dimensional accuracy of steel. For example, we use advanced steelmaking technology, such as converter steelmaking combined with refining technology, to effectively remove impurities and improve the purity of steel; equipped with high-precision rolling equipment to ensure that the thickness of steel is uniform and the shape is regular, meeting the strict requirements of different customers for steel quality.

3. Strict quality inspection system: We have established a complete and strict quality inspection system, and every link is carefully inspected from the entry of raw materials to the delivery of finished products. We have a professional quality inspection laboratory equipped with advanced testing instruments, such as spectrometers, universal testing machines, ultrasonic flaw detectors, etc., which can comprehensively test the chemical composition, tensile strength, yield strength, elongation, weld quality (if any) and other indicators of steel. Only steel products that have undergone strict testing and are all qualified will flow into the market, ensuring that every piece of steel that customers get is a fine product.

4. Multi-material coverage: Our product line is rich and diverse, covering a variety of common steel materials, including carbon steel, alloy steel, stainless steel, etc. Whether it is ordinary carbon steel needed for building structures, high-strength alloy steel used in machinery manufacturing, automotive industry and other fields, or stainless steel with extremely high corrosion resistance requirements, customers can find suitable products in our company to meet the diverse needs of different industries and different application scenarios.

5. Outstanding cost-effectiveness: Although we have made great efforts in cost control, we have never sacrificed product quality in exchange for low prices. On the contrary, we provide customers with cost-effective steel products based on high-quality product quality and reasonable pricing strategies. When customers buy our steel, they can enjoy high-quality product guarantees and relatively affordable prices, which truly achieves value for money.

6. Professional sales team: We have a professional sales team that not only knows the various performance and characteristics of steel products, but also has rich industry experience and good communication skills. We can accurately understand customer needs, provide customers with professional product consultation and purchase suggestions, and help customers quickly and accurately select the most suitable steel products for themselves.

7. Perfect after-sales service: We are well aware of the importance of after-sales service to customer satisfaction, so we have established a perfect after-sales service system. We provide product quality assurance and return and exchange services. During the quality assurance period, if there are quality problems with the product, we will promptly handle the return and exchange procedures for customers; provide technical support and consulting services, and provide timely and accurate answers to various problems encountered by customers in the process of using steel, such as application guidance, processing technology suggestions, etc.; at the same time, we provide good logistics and delivery services, track logistics transportation and assist customers in delivery acceptance; we also actively collect customer feedback and handle it in a timely manner, and continuously improve service quality.