2205 high quality duplex stainless steel plate

specification

|

Product Name |

2205 duplex stainless steel plate |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Thickness |

0.3mm-200mm |

|

Width |

40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. |

|

Length |

2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

|

Country of origin |

China |

|

Main Applications |

1.Oil and Gas Industry: Due to its excellent corrosion resistance, 2205 stainless steel is often used in oil and gas extraction and transportation equipment. |

|

2.Chemical industry: In chemical processing equipment, 2205 stainless steel is widely used in reactors, heat exchangers, pipelines and storage tanks. |

|

|

3.Marine Engineering: Due to its good resistance to seawater corrosion, 2205 stainless steel is suitable for offshore platforms, ships and other marine structures. |

|

|

4.Food and Beverage Industry: 2205 stainless steel is also used in food processing equipment and storage containers because it meets hygiene standards. |

|

|

5.Architecture and Structure: In the construction industry, 2205 stainless steel can be used for building facades, railings and other structural parts due to its beauty and durability. |

|

|

6.Pulp and Paper Industry: In papermaking equipment, 2205 stainless steel is widely used due to its corrosion resistance and strength. |

|

|

Package |

Bundling packaging、Wooden box packaging、Plastic film packaging、Pallet packaging、Anti-rust oil coating、Bubble film packaging |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

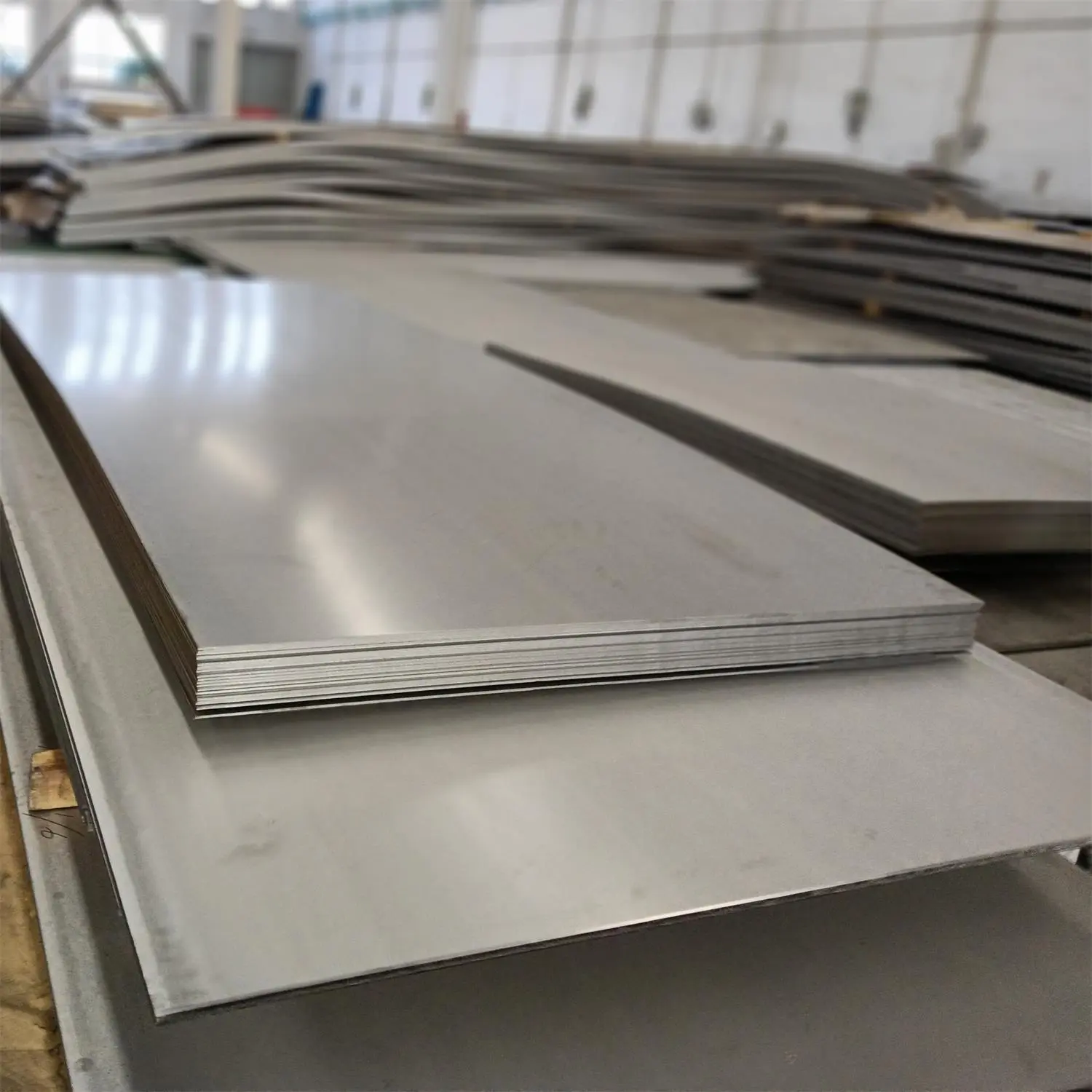

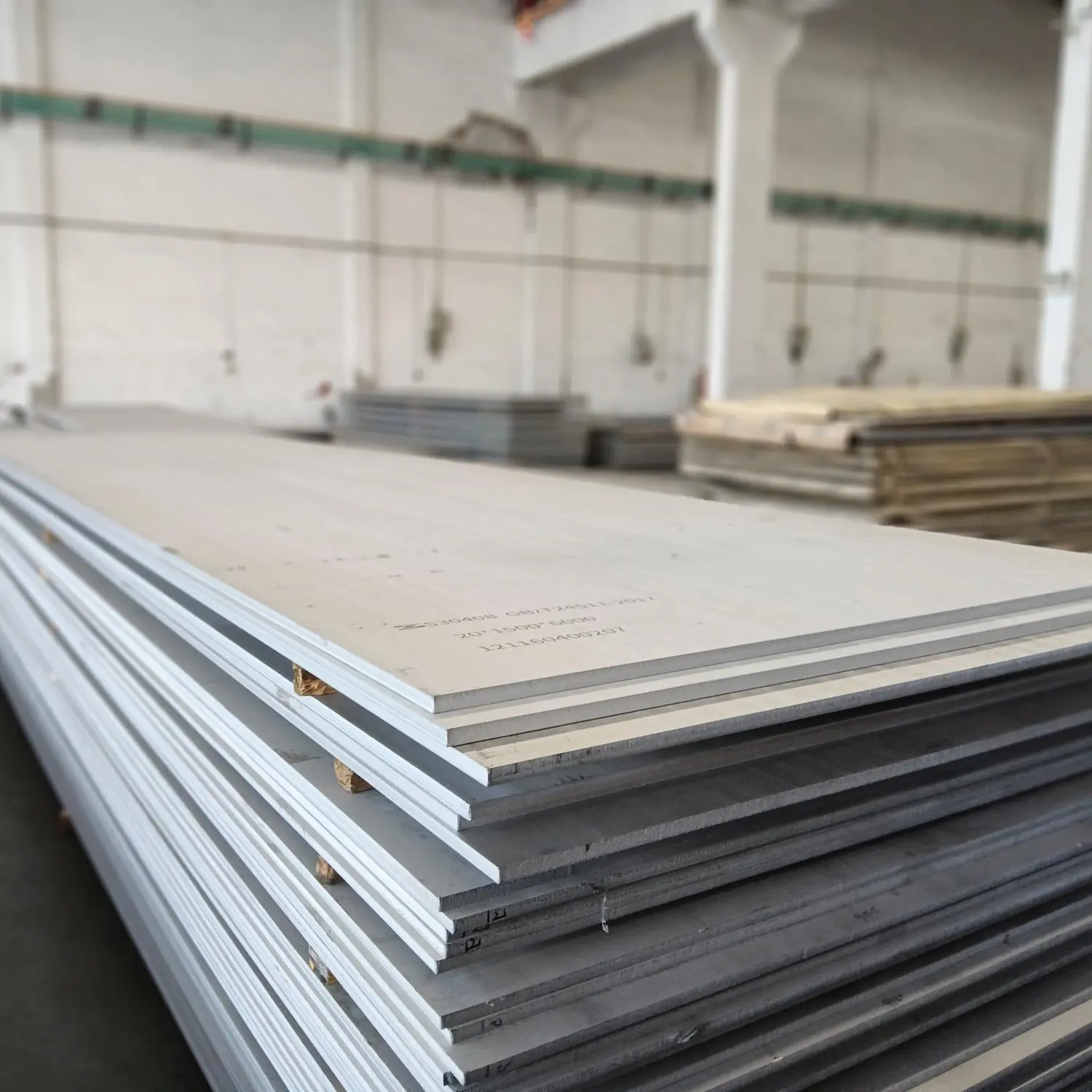

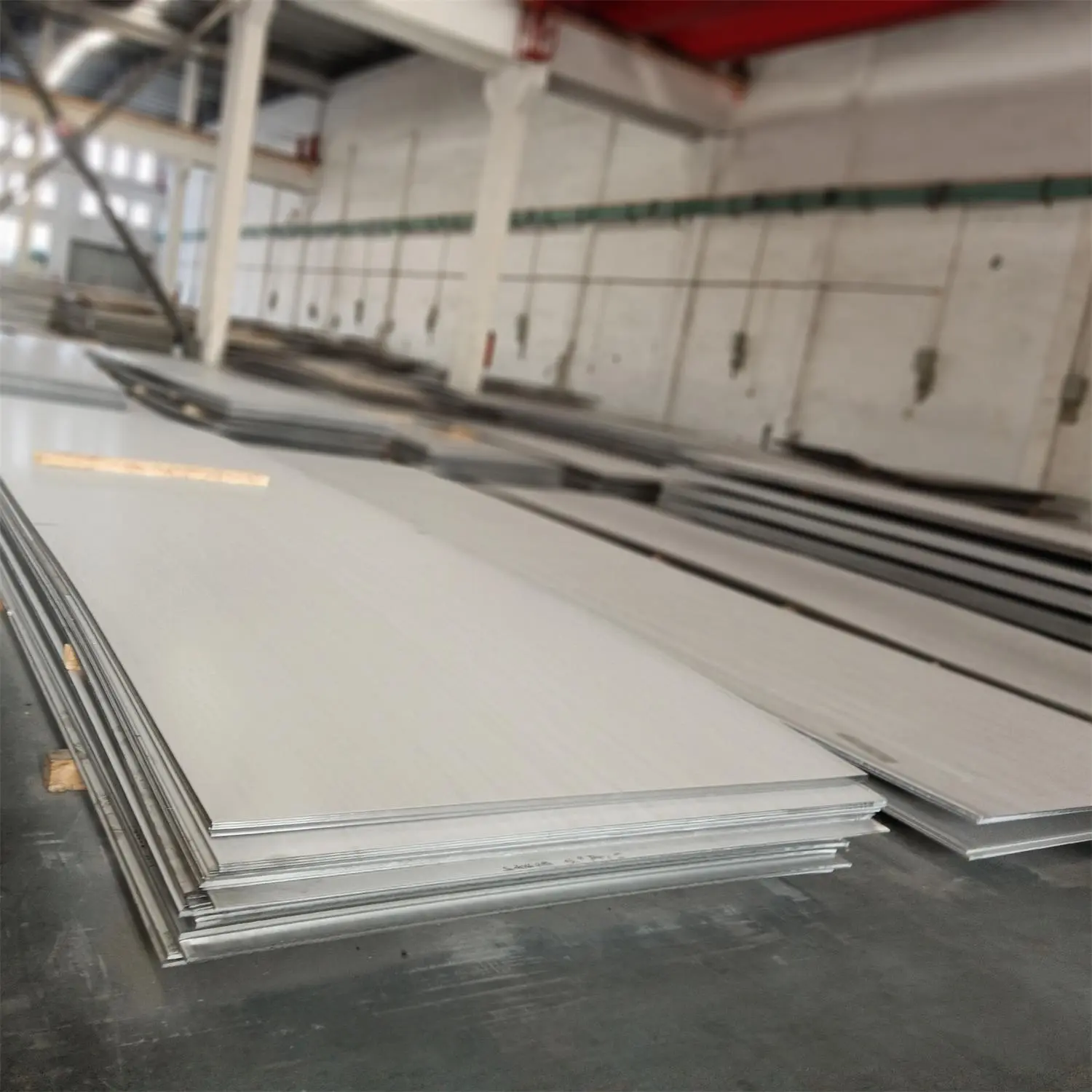

Product Display

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

Mo |

S |

P |

|

≤ 0.03 |

≤1.0 |

≤ 2.0 |

21.0~23.0 |

4.5~6.5 |

2.5~3.5 |

≤ 0.02 |

≤ 0.03 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥620 |

≥450 |

≥25 |

≤ 293HRB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.88 |

190 |

13.7 |

19.0 |

80 |

Surface Selection