201 high quality stainless steel pipe

specification

|

Product Name |

201 stainless steel pipe |

|

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

|

Outer diameter |

Round Pipe |

4mm-200mm |

|

Square Pipe |

10*10mm-100*100mm |

|

|

Rectangular Pipe |

10*20mm-50*100mm |

|

|

Wall Thickness |

0.6mm-6.0mm |

|

|

Length range |

1-6 meters, Length can be customized |

|

|

Error |

±1% |

|

|

Certification |

ISO 9001 ,CE,API |

|

|

Surface treatment |

Black, Bright Polished, Rough Turning, Matt Surface Treatment, No. 4. BA, etc. |

|

|

Country of origin |

China |

|

|

Main Applications |

1.Architectural decoration: 201 stainless steel pipes are often used in decorative structures such as facades, railings, handrails, etc. of buildings because of their beautiful appearance and durability. |

|

|

2.Furniture manufacturing: In the furniture industry, 201 stainless steel pipes are widely used in the frames and supporting parts of furniture such as tables, chairs, and bed frames. |

||

|

3.Automobile industry: Used in automobile exhaust systems, body structural parts, etc. due to its corrosion resistance and strength. |

||

|

4.Food Industry: In food processing and storage equipment, 201 stainless steel pipes are widely used due to their good hygienic properties. |

||

|

5.Chemical industry: used for chemical equipment and pipelines, able to withstand certain corrosive media. |

||

|

6.Mechanical Manufacturing: In some mechanical equipment, 201 stainless steel pipes are used as structural parts and connectors. |

||

|

7.Medical devices: In some medical devices and equipment, it is used due to its corrosion resistance and easy cleaning. |

||

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

|

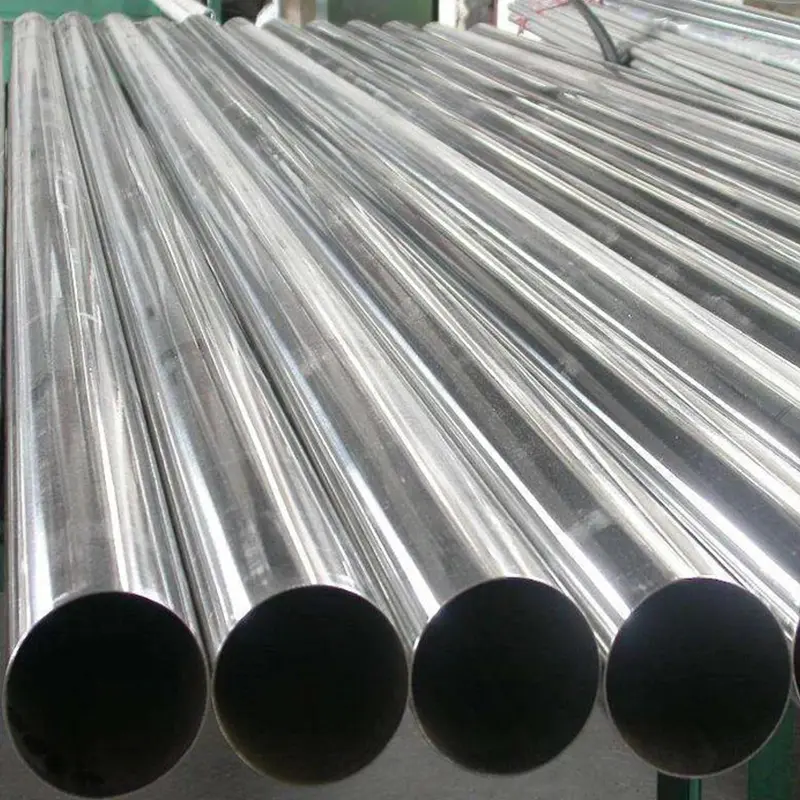

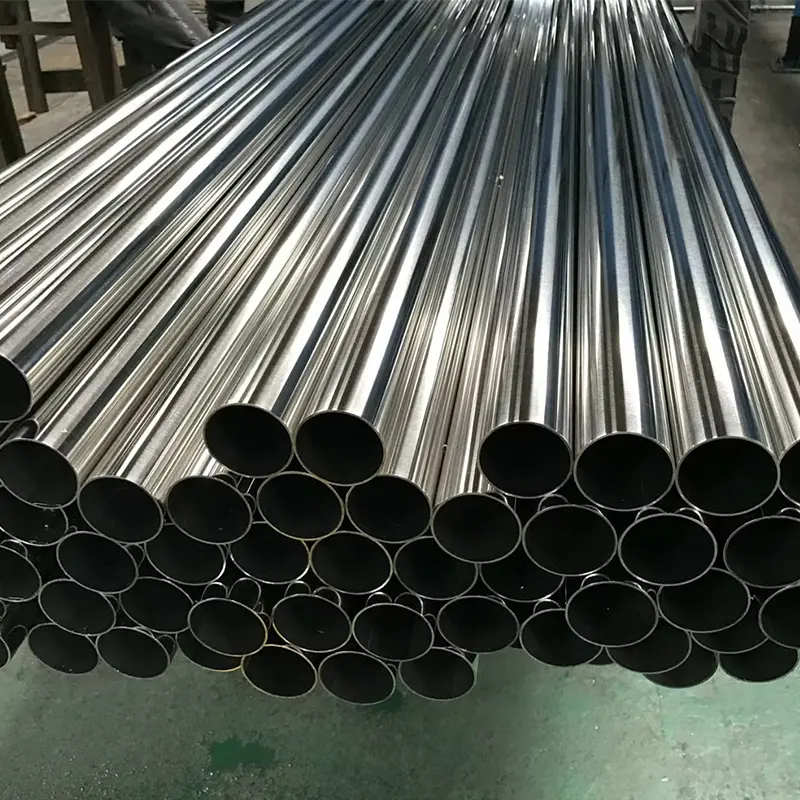

Product Display

Chemical Composition

|

C |

Si |

Mn |

Cr |

Ni |

S |

P |

|

≤ 0.15 |

≤ 0.75 |

5.50~7.50 |

16.00~18.00 |

3.50~5.50 |

≤ 0.03 |

≤ 0.06 |

Mechanical Properties

|

Tensile Strength Kb (MPa) |

Yield Strength σ0.2 (MPa) |

Elongation D5 (%) |

Hardness |

|

≥520 |

≥275 |

≥55-60 |

≤183HB;≤ 100 HRB |

Physical Performance

|

Density(g/cm³) |

Modulus of Elasticity(Gpa) |

Coefficient of Thermal Expansion(10-6/°C) |

Coefficient of Thermal Conductivity(W/m*K) |

Resistivity(ΜΩ. cm) |

|

7.8 |

197 |

15.7 |

16.2 |

27 |

Production process

Raw material preparation:

Select appropriate alloying elements, such as chromium, nickel, manganese, etc., to ensure that it meets the standards of stainless steel.

Smelting:

The raw materials are placed in an electric arc furnace or induction furnace for melting to form stainless steel liquid. The temperature and composition need to be controlled during the melting process to ensure the uniformity of the alloy.

Casting:

Molten stainless steel is poured into a mold and cooled to form an ingot or block.

Hot rolling:

After the ingot is heated to a certain temperature, it is rolled through a hot rolling mill and gradually rolled into the required pipe blank.

Cold rolled or cold drawn:

The tube blank is cold rolled or cold drawn to improve its strength and surface finish to achieve the required tube diameter and wall thickness.

Welding (if applicable):

For seamless pipes, welding is usually not required, whereas for welded pipes, the edges of the pipe blanks are heated and welded together.

Heat treatment:

Heat treatment of the pipe to eliminate internal stress and improve its mechanical properties and corrosion resistance.

Pickling and passivation:

Remove surface oxides and impurities by pickling, followed by passivation to improve corrosion resistance.

.Inspection and testing:

Carry out various inspections on finished products, including size, appearance, mechanical properties and chemical composition, to ensure they meet the standards.

Cutting and Packaging:

Cut the stainless steel pipes into required lengths according to customer needs and pack them for shipment.