20# low alloy high strength spiral welded pipe

specification

|

Product Name |

20# spiral welded pipe |

|

Standard |

ASTM,JIS,DIN,GB,AISI,DIN,EN |

|

Material |

20#、AISI 1020、C22、S20C、EN3 |

|

Outer diameter range |

Small diameter: Usually starts at 219 mm (about 8 inches). Large diameter: can reach 3000 mm (about 120 inches) or larger. |

|

Thickness range |

Small diameter pipe (e.g. 219 mm OD): wall thickness is usually between 5 mm and 12 mm. Medium diameter pipe (e.g. 325 mm to 508 mm OD): wall thickness is usually between 6 mm and 16 mm. Large diameter pipe (such as 720 mm and above outer diameter): wall thickness can be 8 mm to 25 mm or thicker. |

|

Length range |

The longest length is 12 meters, and can be customized by customers |

|

Error |

±1% |

|

Certification |

ISO 9001 ,CE,API |

|

Surface treatment |

Hot dip galvanizing, spraying, anti-corrosion coating, pickling, polishing |

|

Country of origin |

China |

|

Main Applications |

1.Oil and gas transportation: 20# spiral welded pipe is commonly used in oil and gas transportation pipelines and can withstand high pressure and corrosive environment. |

|

2.Water conservancy projects: used in water pipes, irrigation systems and drainage systems, suitable for conveying various liquids. |

|

|

3.Chemical industry: In chemical plants, 20# spiral welded pipes are used to transport chemical media and can resist certain corrosion. |

|

|

4.Construction Engineering: Used in building structures, supports and frames, etc. to provide strength and stability. |

|

|

5.Electric power industry: In power engineering, 20# spiral welded pipe can be used for the supporting structure of transmission lines. |

|

|

6.Mechanical Manufacturing: Used to manufacture various mechanical equipment and parts, especially in situations where high strength and wear resistance are required. |

|

|

7.Municipal engineering: used for the construction of urban infrastructure such as water supply, drainage and heating pipelines. |

|

|

Package |

Simple packaging, reinforced packaging, wooden frame, metal frame, pallet, wrapping |

|

Payment Term |

TT, LC,Cash, Paypal, DP, DA,Western Union or Others. |

|

After-sales service |

1. Quality assurance period 2. Return and exchange policy 3. Delivery and acceptance assistance 4. Customer feedback collection |

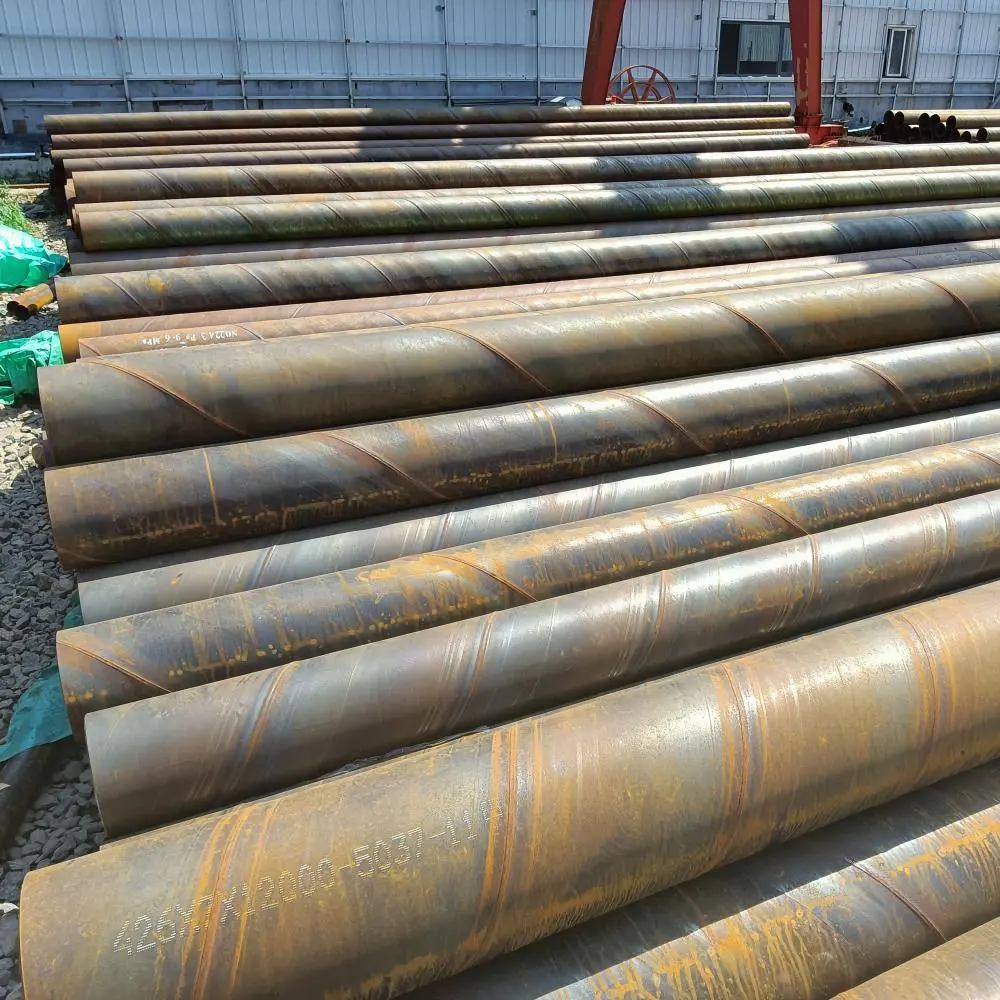

Product Display

Chemical Composition

|

20# |

Carbon (C) |

Silicon (Si) |

Manganese (Mn) |

Chromium (Cr) |

Nickel (Ni) |

Copper (Cu) |

Sulfur (S) |

Phosphorus (P) |

|

|

0.17 - 0.23 |

0.17 - 0.37 |

0.35 - 0.65 |

≤ 0.25 |

≤ 0.30 |

≤ 0.25 |

≤ 0.035 |

≤ 0.035 |

Mechanical Properties

|

Properties |

Values |

|

Tensile Strength (MPa) |

410 - 550 |

|

Yield Strength (MPa) |

245 |

|

Elongation (%) for δ ≤ 16mm |

24 |

|

Elongation (%) for 16 - 30mm |

22 |

|

Impact Energy Kv2 (J) at ≥ 40°C |

27 |

Production process

.Raw Material Preparation:

Steel plates or coils are selected based on the required specifications for the pipe.

.Plate Cutting:

The steel plates are cut into specific widths according to the desired diameter of the pipe.

.Edge Milling:

The edges of the cut plates are milled to ensure proper alignment and fit during the welding process.

.Forming:

The flat steel plates are heated and then formed into a spiral shape using a series of rollers. This process creates the initial pipe shape.

.Welding:

The edges of the formed steel are welded together using a spiral welding technique. This can be done using various welding methods, such as submerged arc welding (SAW) or gas metal arc welding (GMAW).

.Cooling:

After welding, the pipe is allowed to cool down to room temperature.

.Inspection:

The welded pipe undergoes various inspections, including visual inspection, ultrasonic testing, and radiographic testing, to ensure the quality and integrity of the welds.

.Surface Treatment:

The surface of the pipe may undergo treatments such as cleaning, coating, or galvanizing to enhance corrosion resistance.

.Cutting to Length:

The finished pipes are cut to the required lengths based on customer specifications.

.Packaging and Delivery:

The pipes are packaged for transportation and delivered to the customer.