1060 Aluminum Coil with Good Conductivity

specification

|

Products Name |

1060 Aluminum Coil |

||

|

Alloy/Grade |

1050, 1060, 1070, 1100, 1200, 2024, 3003, 3104, 3105, 3005, 5052, 5754, 5083, 5251, 6061, 6063, 6082, 7075, 8011, 8079, 8021 |

||

|

Temper |

F, O, H |

MOQ |

5T for customized, 2T for stock |

|

Thickness |

0.014mm-20mm |

Packaging |

Wooden Pallet for Strip & Coil |

|

Width |

60mm-2650mm |

Delivery |

15-25days for production |

|

Material |

CC & DC route |

ID |

76/89/152/300/405/508/790/800mm |

|

Type |

Strip, Coil |

Origin |

China |

|

Standard |

GB/T, ASTM, EN |

Loading Port |

Any port of China, Shanghai & Ningbo & Qingdao |

|

Surface |

Mill Finish, Anodized, Color coated PE Film Available |

Delivery Methods |

By sea: Any port in China |

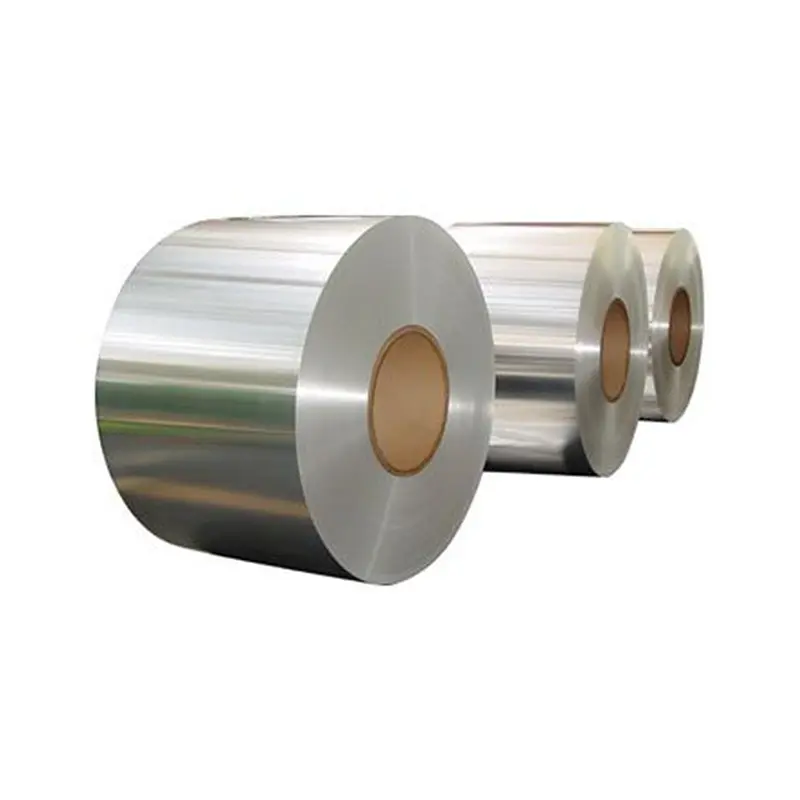

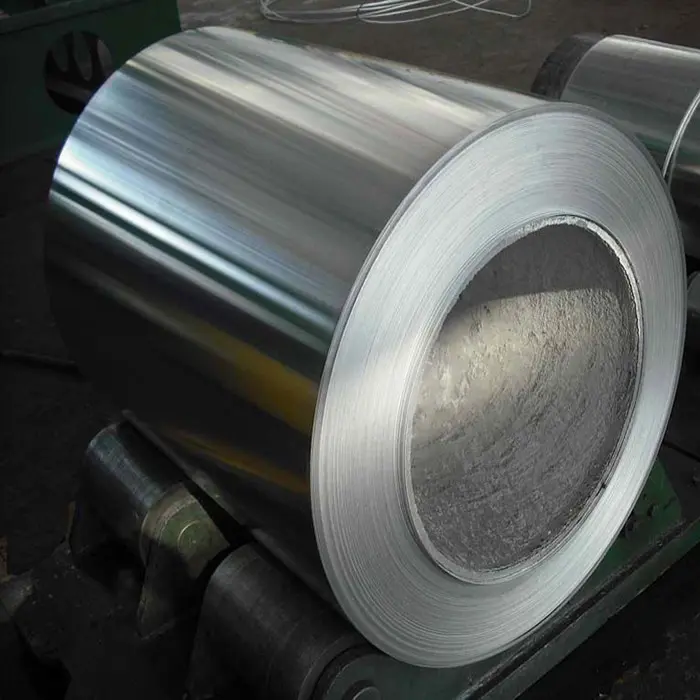

Product Display

Chemical Composition

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others: Each |

Others: Total |

Al: Min. |

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

- |

0.05 |

0.03 |

0.03 |

- |

99.60 |

Mechanical Properties

| Tensile Strength (MPa) | Test Stress 0.2% (MPa) | Elongation Rate D10 (%) | Tensile Strength (MPa) |

| 110-136 | ≥75 | 3-5 | 110-136 |

Physical Performance

| Density | Melting Point | Modulus of Elasticity | Thermal Conductivity |

| 2.7 Kg/m³ | 649 °C | 70-80 GPa | 234 W/m.K |

Annealing State

|

Brand |

Annealing State |

|

1xxx: 1050, 1050A, 1060, 1100 |

O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

|

3xxx: 3003, 3004, 3005, 3105 |

|

|

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 |

O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

|

6xxx: 6061, 6082 |

T4, T6, T451, T651 |

|

2xxx: 2024 |

T3, T351, T4 |

|

7xxx: 7075 |

T6, T651 |

Scope of Application

|

Aluminum Uses And Application Area |

|

|

Food Packaging |

Beverage can ends, cans, bottle caps, etc. |

|

Building |

Curtain walls, cladding, suspended ceilings, thermal insulation, venetian blinds, etc. |

|

Transportation |

Auto parts, passenger car bodies, aviation ships and air cargo containers. |

|

Electronic Equipment |

Electrical appliances, communication equipment,PCPlate drilling guide, lighting and heat dissipation materials, etc. |

|

Consumer Goods |

Umbrellas, cooking utensils, sports equipment, etc |

|

Other |

Military, color coated aluminum plate |